- Overview

- Recommended Products

Introducing, the Mars’s Automatic High Speed Liquid Nitrogen Dispenser Machine System, a cutting-edge solution for efficiently dispensing liquid nitrogen with precision and speed. Whether you are in the food industry, medical field, or conducting scientific research, this innovative dispenser machine is designed to meet your needs with ease.

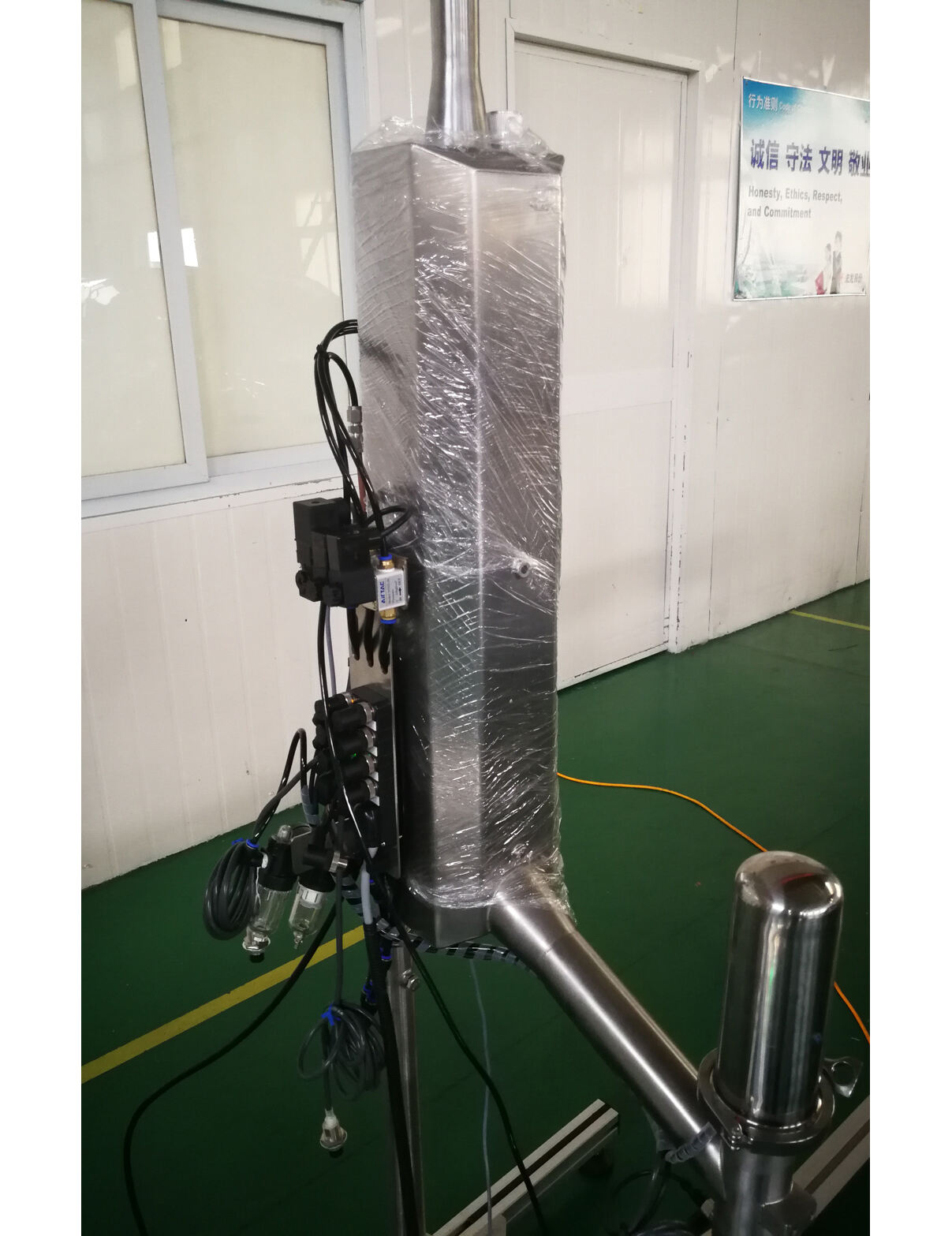

With a sleek and modern design, the Mars’s Automatic High Speed Liquid Nitrogen Dispenser Machine System is not only visually appealing but also highly functional. The machine is equipped with advanced technology that allows for automatic dispensing of liquid nitrogen at high speeds, saving you time and effort in your daily operations.

This dispenser machine system is perfect for businesses and organizations that require a reliable and efficient method of dispensing liquid nitrogen. The Mars brand is known for its commitment to quality and innovation, and this product is no exception. You can trust that the Mars Automatic High Speed Liquid Nitrogen Dispenser Machine System will perform flawlessly and consistently, ensuring that your operations run smoothly and efficiently.

One of the key features of this dispenser machine system is its high speed capabilities. With the ability to dispense liquid nitrogen quickly and accurately, you can increase productivity in your workplace and streamline your processes. This is especially important for industries where time is of the essence and precision is crucial.

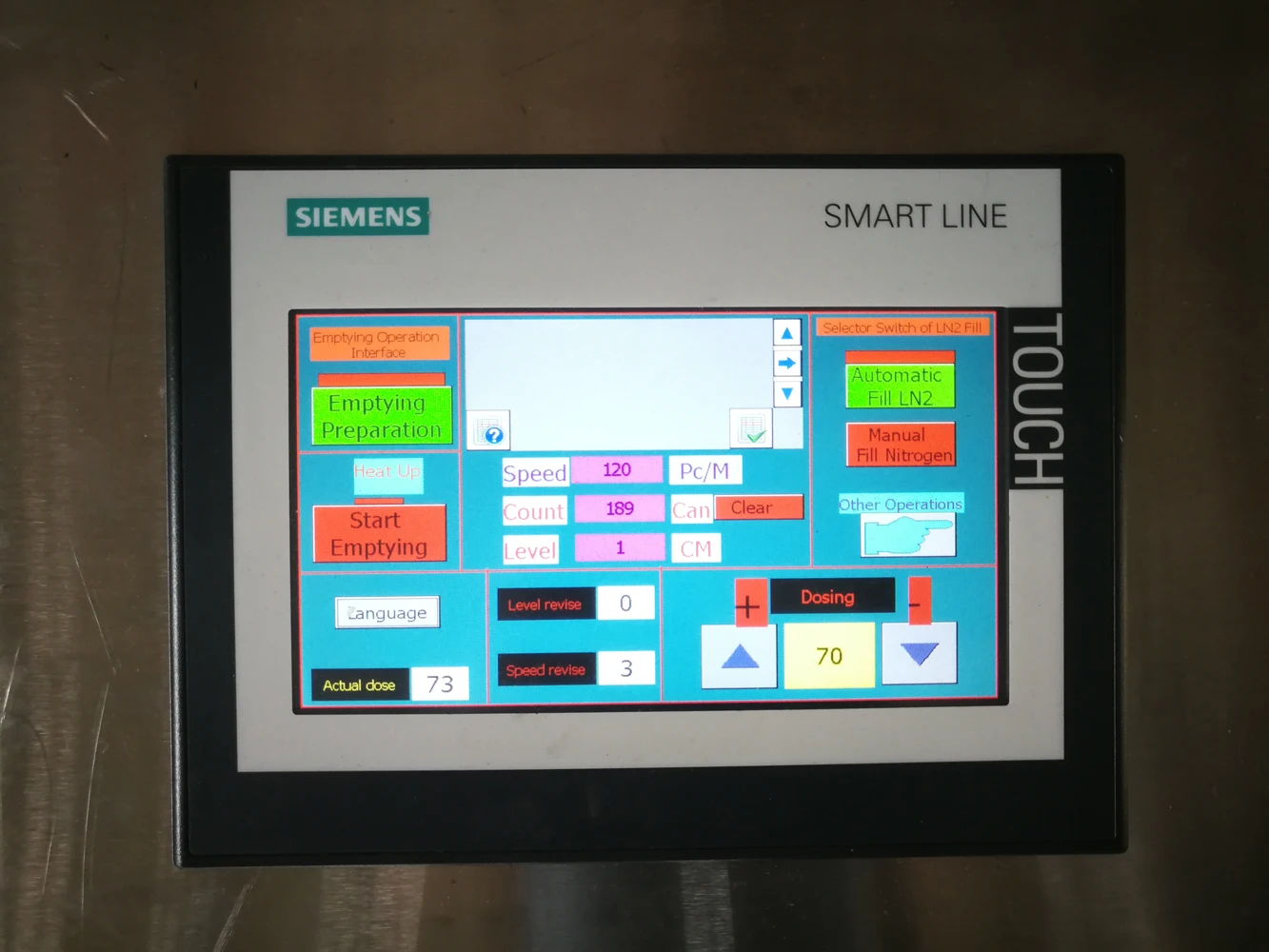

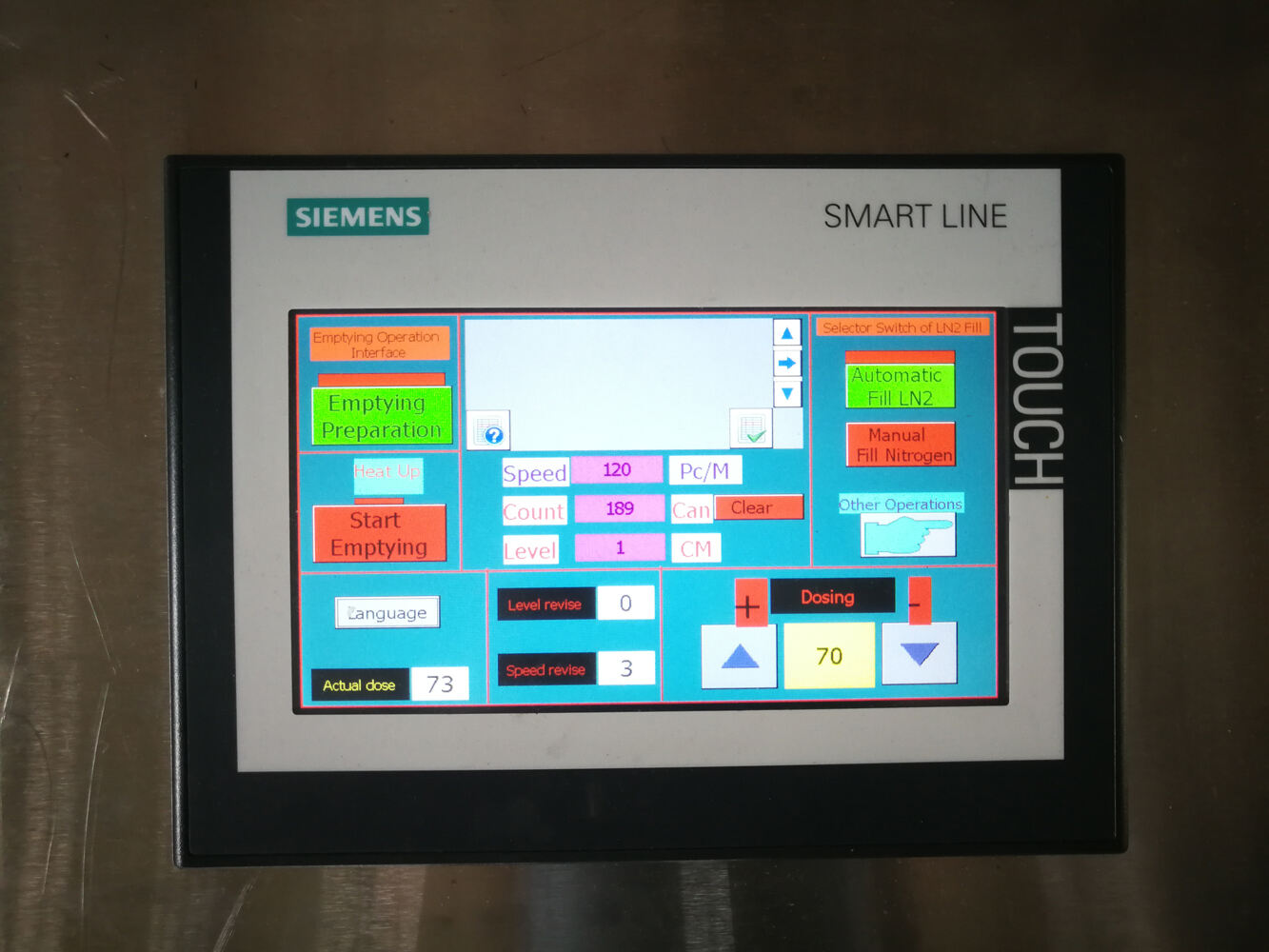

In addition to its speed, the Mars’s Automatic High Speed Liquid Nitrogen Dispenser Machine System also offers a user-friendly interface that makes it easy to operate. The machine is designed with convenience in mind, allowing you to adjust settings and monitor performance with ease. This ensures that you can focus on your work without any unnecessary distractions.

The Mars’s Automatic High Speed Liquid Nitrogen Dispenser Machine System is a top-of-the-line product that is sure to enhance your operations and improve efficiency. With its cutting-edge technology, high-speed capabilities, and user-friendly design, this dispenser machine system is a must-have for any business or organization that relies on liquid nitrogen dispensing. Trust in the Mars brand for quality and reliability, and experience the difference that this innovative product can make in your daily operations

Automatic High Speed Liquid nitrogen dispenser Machine System

Tin cans are gradually replaced by aluminum cans, plastic cans, but alumium can and plastic must be add pressure, to make the body not deformation, liquid nitrogen injection is an ideal solution, when the liquid nitrogen tank volume expansion after gasification 700 times, can be formed in the tank after put the air out of the vacuum, also can increase the jar inner pressure, keep while prolong the shelf life of tank storage rounded appearance and convenient transportation. My company reference, draw lessons from foreign advanced equipment, developed this product to fill the blank of the industry

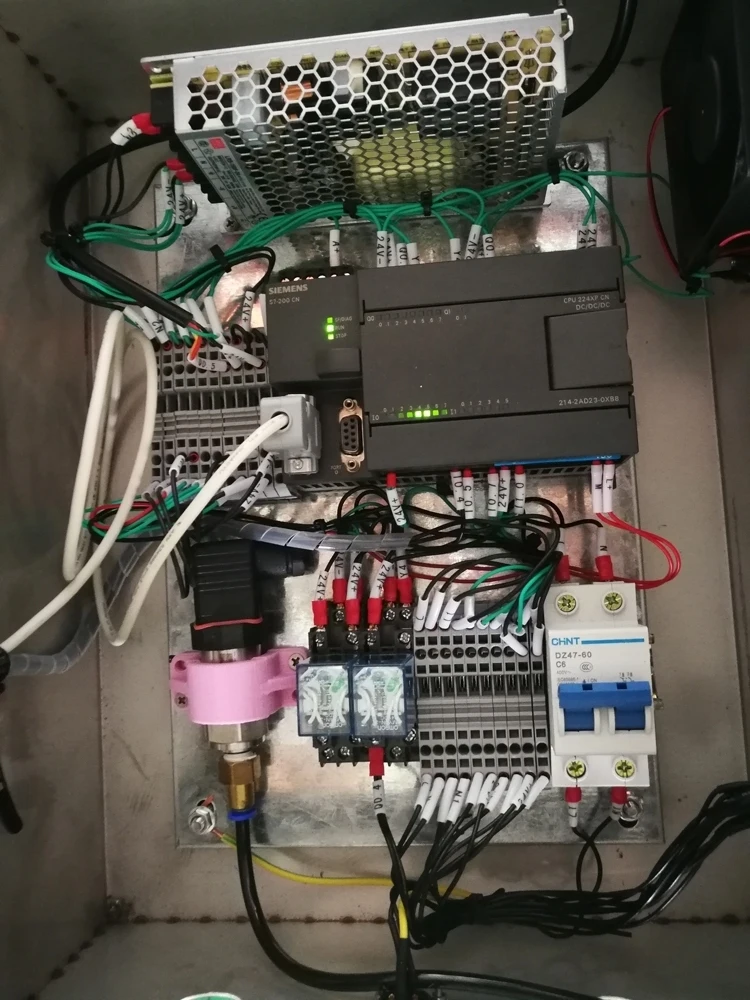

Can accurately control the liquid nitrogen quantity, the product has no container no nitrogen filling, Siemens PLC programming control and touch screen control system, set a simple convenient and easy to understand, compact appearance, easy installation can cooperate with any production line, the whole line adopts vacuum liquid nitrogen thermal insulation pipe, to ensure maximum minimum consumption of liquid nitrogen, no great operating environment

Working conditions

1. Liquid nitrogen supply: 15 (0.1MPa) with liquid nitrogen to mouth connection.

2. Compressed air or nitrogen: used to supply the refill valve work. Need to fell "diameter, pressure range 50-100 psig (3.4 to 6.9 bar). Set pressure 50 psig (0.35MPa), great impact pressure setting is too high, and is not conducive to refill valve core and internal vacuum pipe life

Technical Parameter:

Filling heads |

1 |

Production speed |

0-500cans/Min |

| Suitable can size | any |

| Dosing precision | ±5% |

Liquid nitrogen machine itself liquid nitrogen consumption |

0.2L/H |

| Adjustable dosing time | 15-1000ms |

| Adjustable dosing amount | 0.01-14g/time |

Motor power |

0.1Kw |

Voltage |

220V,50HZ |

Control voltage |

24V, DC/AC |

Overall dimension |

950×177×603mm |

Net weight |

15Kg |

YDJ-300 Liquid Nitrogen Dosing Machine is the latest liquid nitrogen dosing machine in China which uses the similar machines abroad for reference. It could control dosing volume accurately, no-container-no-liquid dosing, small size, easy installation and could coordinate with any filling production line. Control system comprises Siemens PLC and touch screen, all pipes adopt vacuum heat-insulated pipes which could ensure minimum consumption of liquid nitrogen and no frosting operation condition

Working Process:

Liquid nitrogen gasify and volume expansion 700 times, extrude the air out and form vacuum in the can, increase the aluminum can/pet can internal pressure to prolong the canned beverage shelf life and keep good looking for better transportation and store

Operation Conditions:

1. Supple of Liquid Nitrogen: Regulate to 15 (0.1MPa) and connect to liquid nitrogen pipe

2. Compressed Air or Nitrogen: Supply to the working of dosing valve. The pipe diameter must be 1/4inch and pressure range is from 50psig to 100psig (3.4 to 6.9 bar). Set the pressure to 50 psig (0.35MPa). Please do not set the pressure too high, high pressure means high impact, it will shorten the lifetime of dosing valve element and internal vacuum pipe

Characteristics:

1. No container no dose and interval dose method in low speed to reduce liquid nitrogen consumption; dosing valve is always open in high speed. Automatic detects high speed or low speed.

2. Vacuum & heat insulation protection

3. Special nozzle care system effectively avoided nozzle frost and ice blockage phenomenon.

4. Liquid-gas separator ensures liquid nitrogen in a ultra cold state, improves liquid phase purity to make the dose more precision and steady.

5. Liquid nitrogen buffer function, effectively control liquid nitrogen bounce splash. Liquid nitrogen dosing amount is steady and ensures can pressure equality.

6. Filter (optional) 10μm to removes particulate pollution

7. Precise dosing liquid nitrogen speed could reach to 300cpm, continuous dosing speed could reach to 800cpm

8. Capacity adjustability and effectively vacuum liquid nitrogen insulation pipe ensures minimum liquid nitrogen consumption

9. Advanced dosing valve ensures transport pure and liquid nitrogen

10. Lowest outlet pressure of dosing valve ensures minimum liquid nitrogen splash

11. No frost operating condition

12. Precise adjustability of dosing amount and dosing time

13. Continuous self-monitoring through alarm indicator

14. PLC control/Touch screen/user-interface language selectivity

15. Could connect liquid nitrogen vacuum and heat insulation pipe, also could provide a complete liquid supply system from liquid nitrogen storage tank to filling production line

16. Small size and easy to install

17. Diversity machine types ensures to suit different capacity production lines

18. Apply to all different sizes pet bottles and thin-wall easy open cans production lines