Turnkey Project a to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine

- Overview

- Recommended Products

Introducing, the Mars’s Turnkey Project A to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine, a top-of-the-line solution for all your mineral water bottling needs. This high-speed filling machine is designed to handle a capacity of 9000 bottles per hour, making it ideal for large-scale production facilities.

With the Mars’s Turnkey Project A to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine, you can expect a seamless and efficient operation from start to finish. This turnkey project includes everything you need to get your bottling line up and running, from the initial installation to training and maintenance support.

The CGF24-24-8 PET Bottle Mineral Water Filling Machine is equipped with advanced technology to ensure precise filling and sealing of each bottle. The machine features a 24-24-8 configuration, with 24 washing heads, 24 filling heads, and 8 capping heads, allowing for fast and accurate processing of PET bottles.

The Mars Turnkey Project A to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine is designed for easy operation and maintenance. The user-friendly interface allows operators to monitor and control the filling process with ease, while the machine's durable construction ensures long-lasting performance.

Whether you are bottling purified water, spring water, or flavored water, the Mars’s Turnkey Project A to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine is the perfect solution for your bottling needs. This machine is suitable for a wide range of bottle sizes and shapes, making it versatile and efficient for any production line.

Invest in the Mars’s Turnkey Project A to Z Automatic 9000BPH CGF24-24-8 PET Bottle Mineral Water Filling Machine and streamline your bottling process for maximum efficiency and productivity. With its high-speed performance, advanced technology, and reliable operation, this machine is the perfect choice for your mineral water bottling operation.

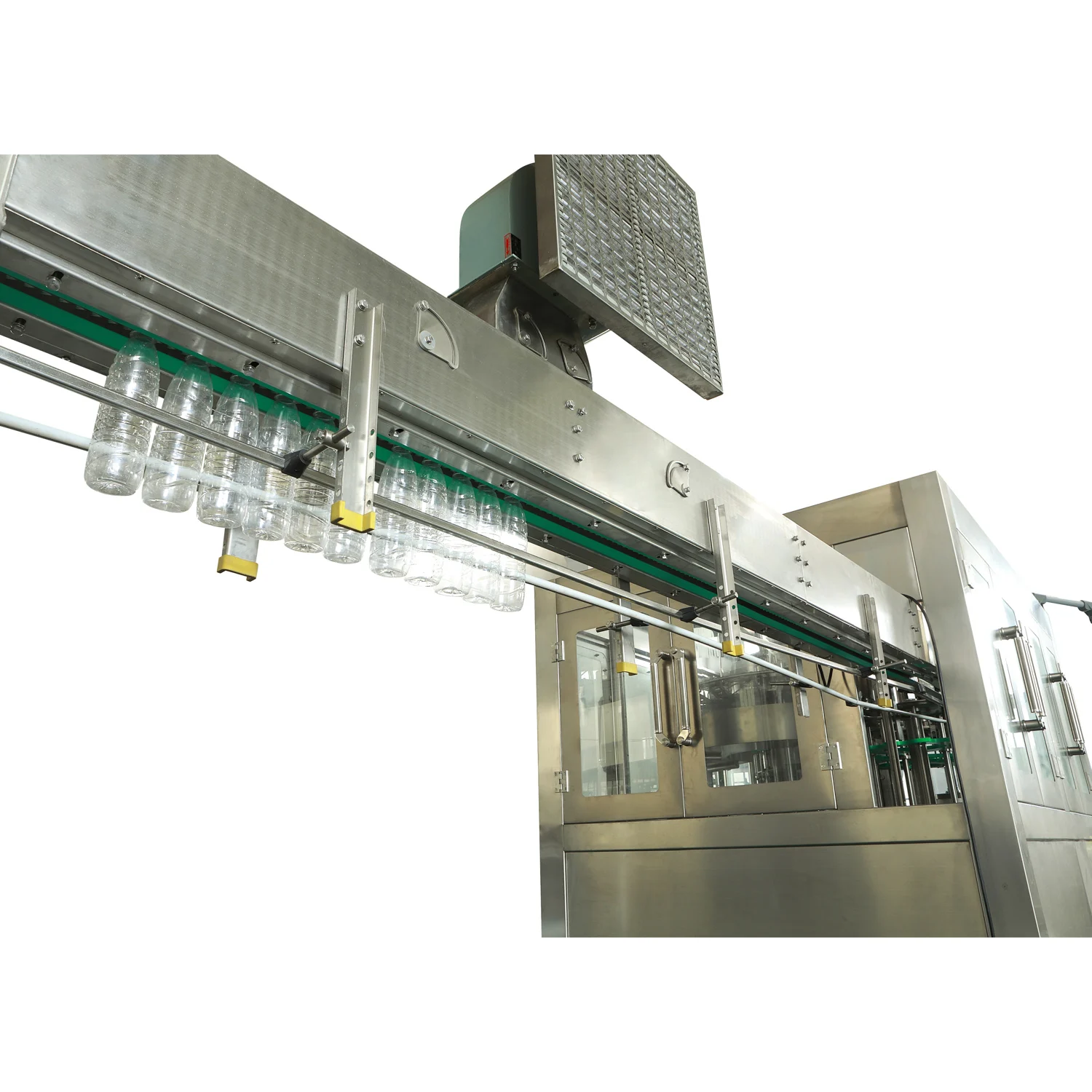

This series of Mineral Water Filing Machine are applied to the production of pure water, mineral water, with optional capacity from 3,000 to 30,000BPH. The washing, filling and capping will be finished just by this one machine. It is very convenient to change bottle size by means of advanced bottle conveying technology--bottle-neck clamping and bottle suspending technology

This machine has compact structure, complete control system and high automation. It is easy to operate, simple to maintain

Filling principle is gravity filling or normal pressure filling. Filling valves are made of stainless steel with high quality

It is suitable for different PET bottles with different shapes. When changing for another bottle type, only need to change the star wheels, no need to adjust machine height

Bottle is transferred by clamping its neck, which avoid the second pollution to bottle. It is equipped with overload protection device which can make sure the machine and workers in safe situation

Control system has the functions of testing caps, stopping work when bottles are blocked and counting capacity, etc.

Main electronical parts and pneumatic parts are from world famous brands, such as MITSUBISHI, Siemens, OMRON, AIRTAC, SCHNEIDER and so on, which make sure the machine has good quality.

Capping head is equipped with magnetic torque device to guarantee good effect of sealing caps and not break the cap. The torque can be designed according to real production demand

Cap feeding system has perfect feeding technology and protection device. When there is no bottle, cap is not delivered.

The machine is controlled by PLC. From bottle going in to bottle going out, the whole process is controlled by micro-computer. Capacity and production speed can be shown on PLC screen. Most of parts on the machine are made of stainless steel 304

Components

1. Driving system

2. Bottle-loading system

3. Bottle-rinsing system

4. Transmittal system between rinsing and filling

5. Filling system

6. Transmittal system between filling and capping

7. Capping system

8. Cap-unscrambling system

9. Bottle-unloading system

10. Frame

11. Electrical system

| Rinsing head | 24 |

| Filling valve | 24 |

| Capping head | 8 |

| Power | 6.57Kw |

| Capacity | 8000-9000bottles per hour |

| Weight | 5500Kg |