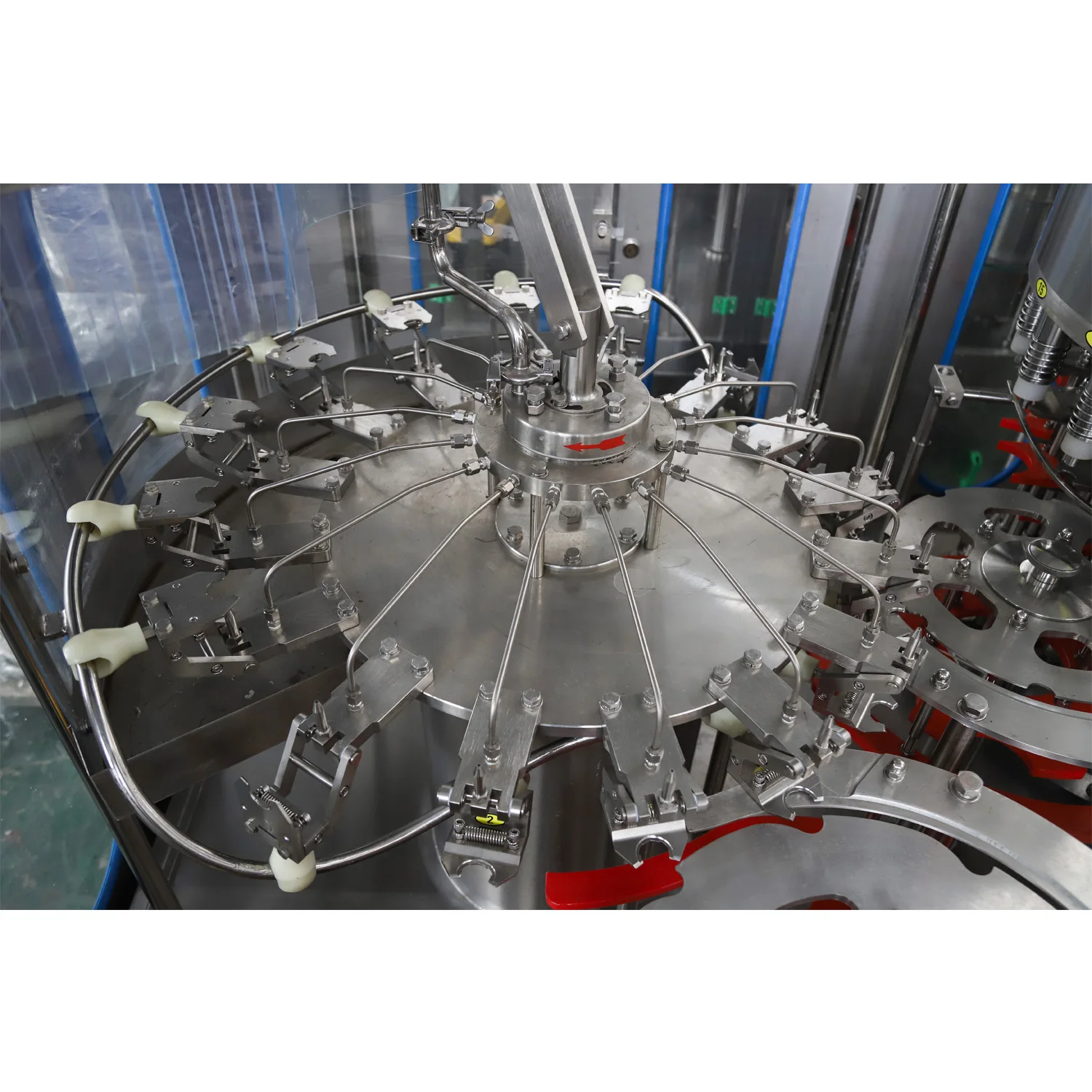

1. All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2. 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3. 304/316 stainless steel washing pump

Mini Mineral Water Plant Filling Machine Plastic Beverage Automatic Bottles Electric Overseas Third-party Support Available

- Overview

- Recommended Products

Introducing, the Mars’s Mini Mineral Water Plant Filling Machine - the perfect solution for small-scale beverage production! This innovative machine is designed to streamline the bottling process and ensure fast, efficient production of mineral water and other beverages.

The Mars’s Mini Mineral Water Plant Filling Machine is made from high-quality plastic materials, making it durable and long-lasting. Its compact size allows it to fit easily into small spaces, making it the ideal choice for businesses with limited space.

With automatic bottle filling capabilities, this machine can fill a large number of bottles in a short amount of time, saving you time and effort. The electric motor ensures smooth and consistent operation, while the overseas third-party support ensures that you will always have access to technical assistance when you need it.

Whether you are looking to start a new beverage business or simply need a reliable machine for your existing operation, the Mars Mini Mineral Water Plant Filling Machine is the perfect choice. Its user-friendly design makes it easy to operate, even for those with little experience in the industry.

With the ability to fill various bottle sizes and shapes, this machine is versatile and adaptable to your specific needs. Whether you are bottling mineral water, juice, or other beverages, the Mars’s Mini Mineral Water Plant Filling Machine will get the job done quickly and efficiently.

Don't let bottling your beverages be a cumbersome and time-consuming task. Invest in the Mars’s Mini Mineral Water Plant Filling Machine and experience the convenience and efficiency of automatic bottle filling. With its high-quality construction and reliable performance, this machine is sure to become an essential part of your beverage production process.

Choose the Mars’s Mini Mineral Water Plant Filling Machine for your business today and take the next step towards increased productivity and success. With its compact size, durable construction, and efficient operation, this machine is the perfect choice for small-scale beverage production

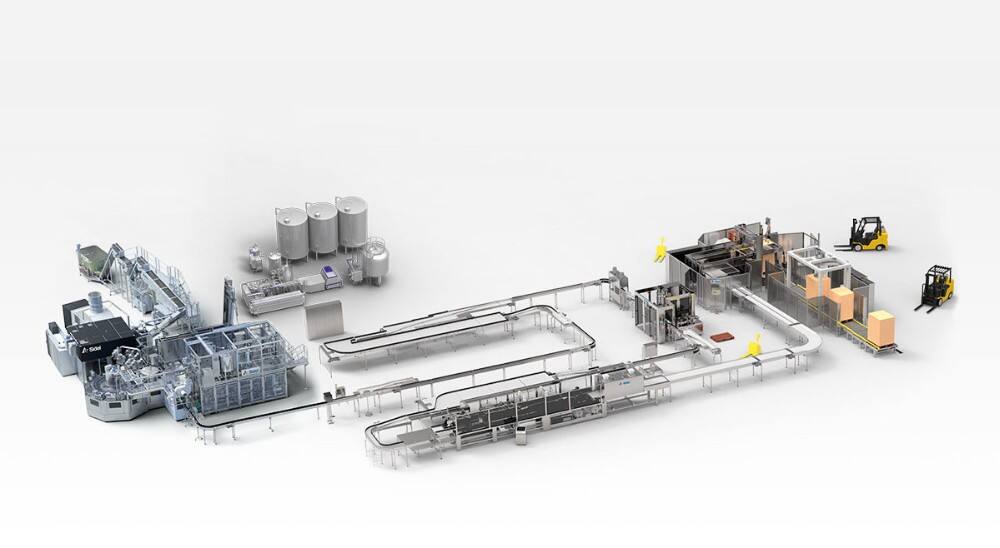

Mini mineral water plant Product Application

This CGF Wash-filling-capping 3-in-1unit: Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. Beverage Machinery can finish all the process such as washing bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency

The Complete Bottled Mineral Water / Pure Water Production Line used in the beverage filling operations. The three functions of bottle wash, fill and seal are composed in one body of the machine. The whole process is automatic

Main Features

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON

Rinsing heads

Filling heads

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

Capping heads

1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2. All 304/316 stainless steel construction

3. No bottle no capping

4. Automatic stop when lack of bottle

New Waterfall type cap elevator

1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary

Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures

Packaging | |

Size |

123 (L) * 456 (W) * 789 - D |

Weight |

2.2 T |

Packaging Details

|

The normal package is wooden box(Size: L*W*H). If export to european countries, the wooden box will be fumigated. If container is too tight, we will use pe film for packing or pack it according to customers special request |