- Overview

- Recommended Products

Introducing, the Small Automatic Glass Bottle Craft Beer Filling Crown Capping Labeling Machine from Mars! This innovative machine is the perfect solution for small breweries looking to streamline their production process and increase efficiency.

With its compact size and user-friendly design, this machine is ideal for small to medium-sized craft breweries. It can fill, crown cap, and label glass bottles with ease, making it a versatile and essential tool for any beer production line.

The automatic filling function ensures a consistent fill level in each bottle, reducing waste and ensuring product quality. The crown capping mechanism securely seals each bottle, preserving the freshness and flavor of your craft beer. Additionally, the labeling feature allows you to customize and brand your bottles with ease.

This machine is designed for maximum efficiency and ease of use. It can easily be adjusted to accommodate different bottle sizes and fill levels, making it versatile and adaptable to your specific production needs. The intuitive controls and digital display make operation simple and straightforward, reducing the need for extensive training or specialized knowledge.

Constructed from high-quality materials, this machine is designed to withstand the rigors of a busy production environment. It is durable, reliable, and built to last, ensuring years of consistent performance and reliable operation.

Whether you are a small craft brewery looking to expand your production capabilities or a larger operation in need of a compact and efficient bottling solution, the Small Automatic Glass Bottle Craft Beer Filling Crown Capping Labeling Machine from Mars is the perfect choice. Upgrade your production line and enhance the quality and consistency of your craft beer with this innovative and reliable machine

Small Automatic Glass Bottle Craft Beer Filling Crown Capping Labeling Machine

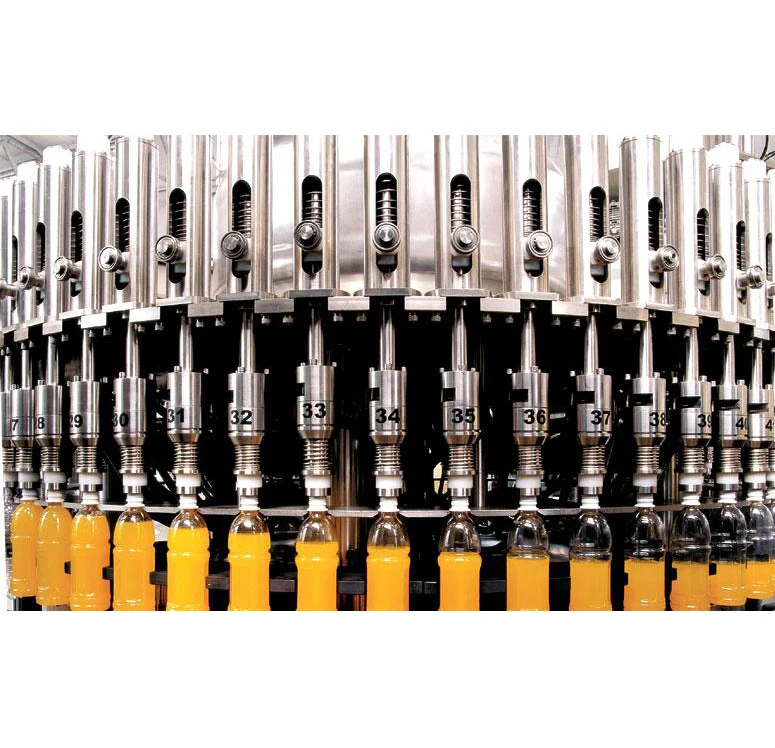

Beer automatic filling line:

Characteristics for Small Beer Bottling Machine :

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON

Model |

Washing heads |

Filling heads |

Capping heads |

Capacity(b/h) 500ml |

Motor power - KW |

Overall dimension - mm |

BGF14-12-5 |

14 |

12 |

5 |

1000bph |

1.5KW |

2100x1400x2500 |

BGF18-18-6 |

18 |

18 |

6 |

2000bph |

2.2KW |

2460x1720x2650 |

BGF24-24-8 |

24 |

24 |

8 |

3000bph |

3KW |

3100x2100x2650 |

BGF32-32-10 |

32 |

32 |

10 |

6000bph |

4KW |

3500x2500x2650 |

BGF40-40-10 |

40 |

40 |

10 |

8000bph |

7.5KW |

4600x1800x2650 |

BGF50-50-12 |

50 |

50 |

12 |

9000bph |

9.5KW |

5200x4500x3400 |

BGF60-60-15 |

60 |

60 |

15 |

12000bph |

12KW |

6500x4500x3400 |