- Overview

- Recommended Products

Introducing, the Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project! This top-of-the-line water purification system is a game-changer when it comes to producing high-quality mineral water. With its cutting-edge technology and user-friendly design, this machine is perfect for businesses looking to establish a reliable and efficient water production operation.

From start to finish, the Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project provides a seamless and hassle-free way to produce mineral water. The fully automatic system takes care of every step of the water purification process, from filtering out impurities to adding essential minerals for a crisp and refreshing taste.

One of the standout features of this machine is its versatility. The Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project is capable of handling various water sources, making it suitable for a wide range of environments. Whether you are using well water, tap water, or spring water, this machine can adapt to meet your specific needs.

In addition to its versatility, the Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project is designed for efficiency. The advanced technology used in this system ensures that water is purified quickly and accurately, saving you time and minimizing waste. This not only improves productivity but also reduces operating costs in the long run.

Furthermore, the Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project is built to last. Made from high-quality materials and constructed with precision, this machine is durable and reliable, ensuring that your water production operation runs smoothly for years to come. With regular maintenance and care, you can count on this machine to consistently deliver top-notch mineral water to your customers.

The Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project is a must-have for businesses looking to establish a successful mineral water production operation. With its advanced technology, versatility, efficiency, and durability, this machine sets the standard for quality and reliability in the industry. Invest in Mars’s A to Z Complete Full Automatic Mineral Water Plant Machine Project today and take your water production to the next level

A to Z Complete Full Automatic Mineral water plant machine project

Description:

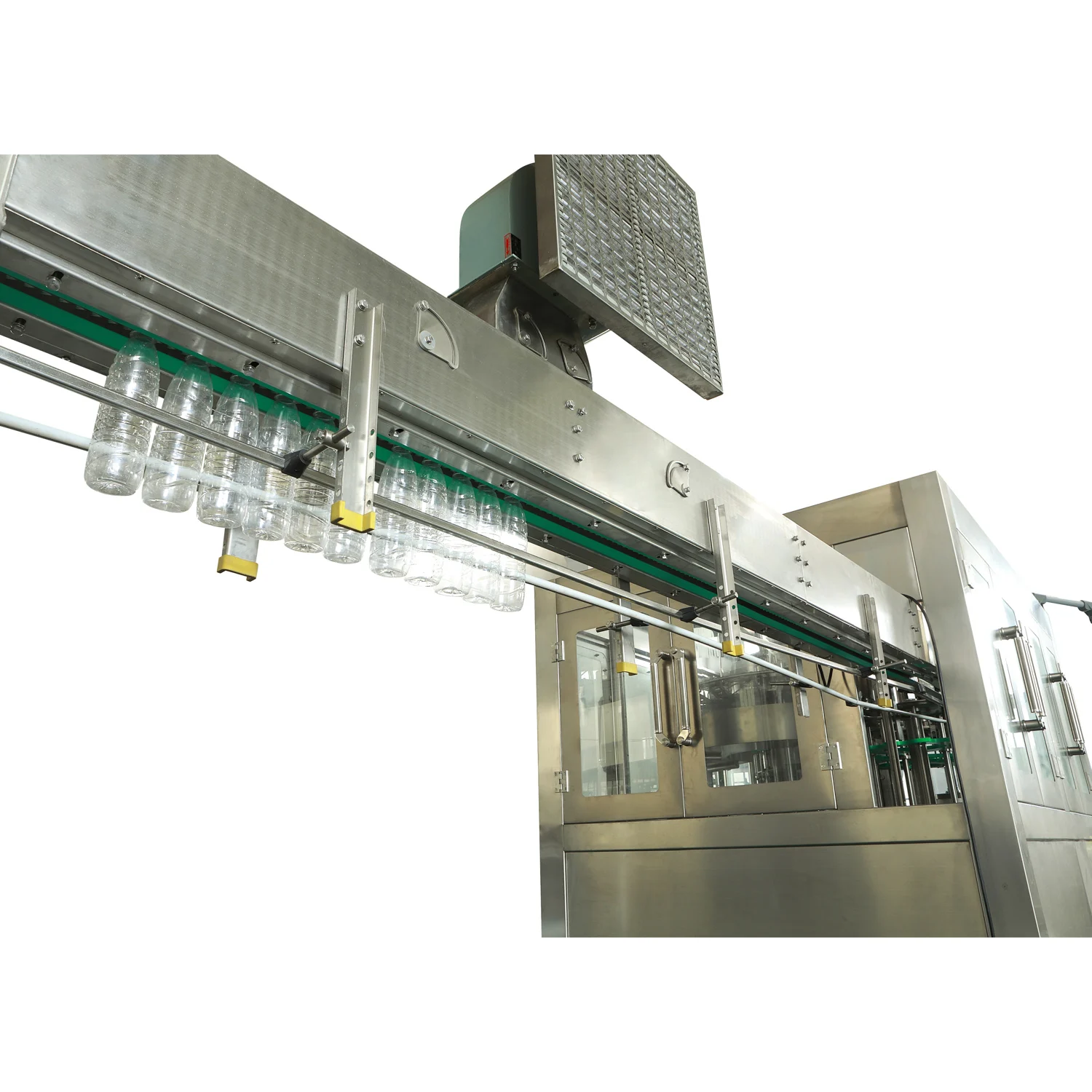

This series of bottle capping machine are used for capping PET bottle

Characteristics for Return Bottle Machine:

1. The washing, filling and capping 3 kinds of jobs will be finished just by this one machine

2. It is very convenient to change diverse sizes of bottles by means of advanced bottle conveying technology--bottleneck clamping and bottle suspending technology

3. Advanced programmable PLC is equipped to control the main machine

4. Main electronic components are all from famous international enterprises, like Siemens, Mitsubishi

5. All spare parts that may touch with water are made from high-quality stainless steel

Main Technical Specifications for Return Bottle Machine

Model: |

CGF14/12/5 |

CGF18/18/6 |

CGF24/24/8 |

CGF32/32/10 |

CGF40/40/12 |

CGF50/50/15 |

Production Capacity:500ml(B/H) |

4000 |

6000 |

10000 |

14000 |

17000 |

20000 |

Suitable Bottle Standard:(mm) |

150-300 |

150-340 |

150-340 |

150-340 |

150-340 |

150-340 |

Suitable Cap Standard - mm: |

φ20-φ60 |

|||||

Filling Pressure:(Mpa) |

0.2-0.3 |

|||||

Filling Model: |

by gravity |

|||||

Power:(KW) |

3.13 |

3.84 |

3.84 |

5.6 |

6.3 |

7.3 |

Filling Temperature: |

Room Temperature

|

|||||

|

Overall Size L×W×H(mm) |

2300×1670×2350 |

2470×1900×2350 |

2865×2170×2350 |

3700×2570×2350 |

3800×2950×2400 |

4500×3400×2400 |

Total Weight:(kg) |

2500 |

3000 |

4000 |

5000 |

6000 |

7000 |

Return Bottle Machine