- Overview

- Recommended Products

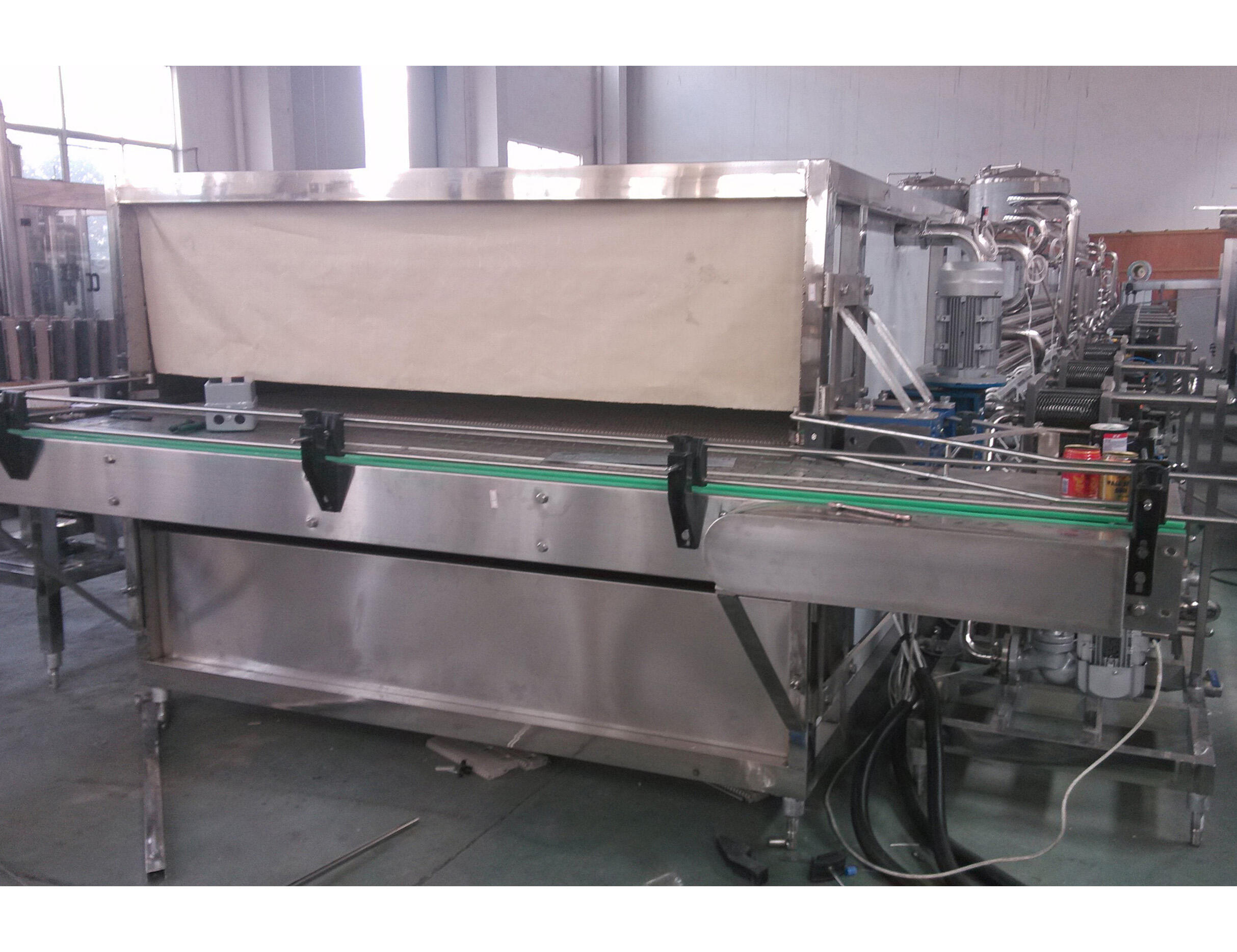

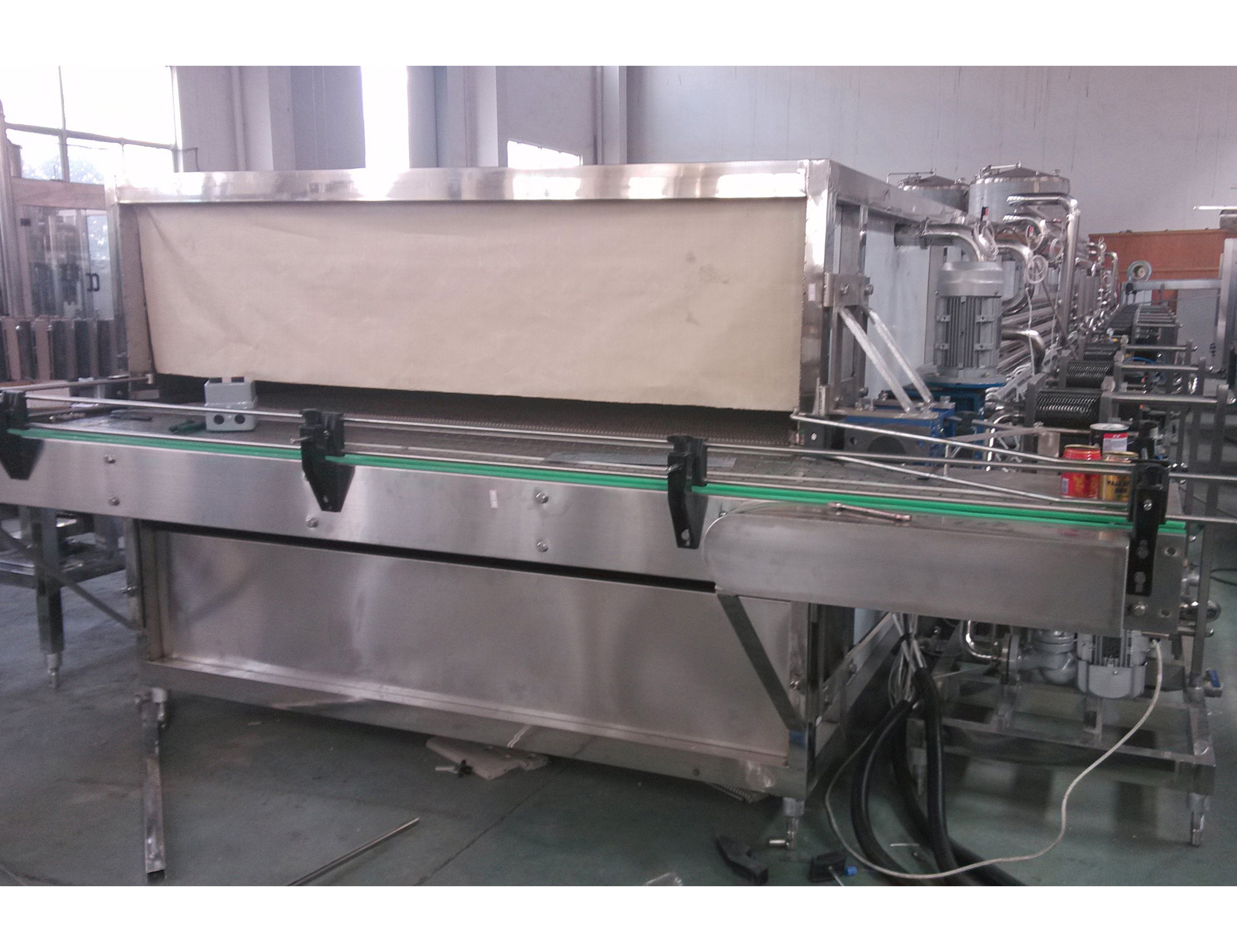

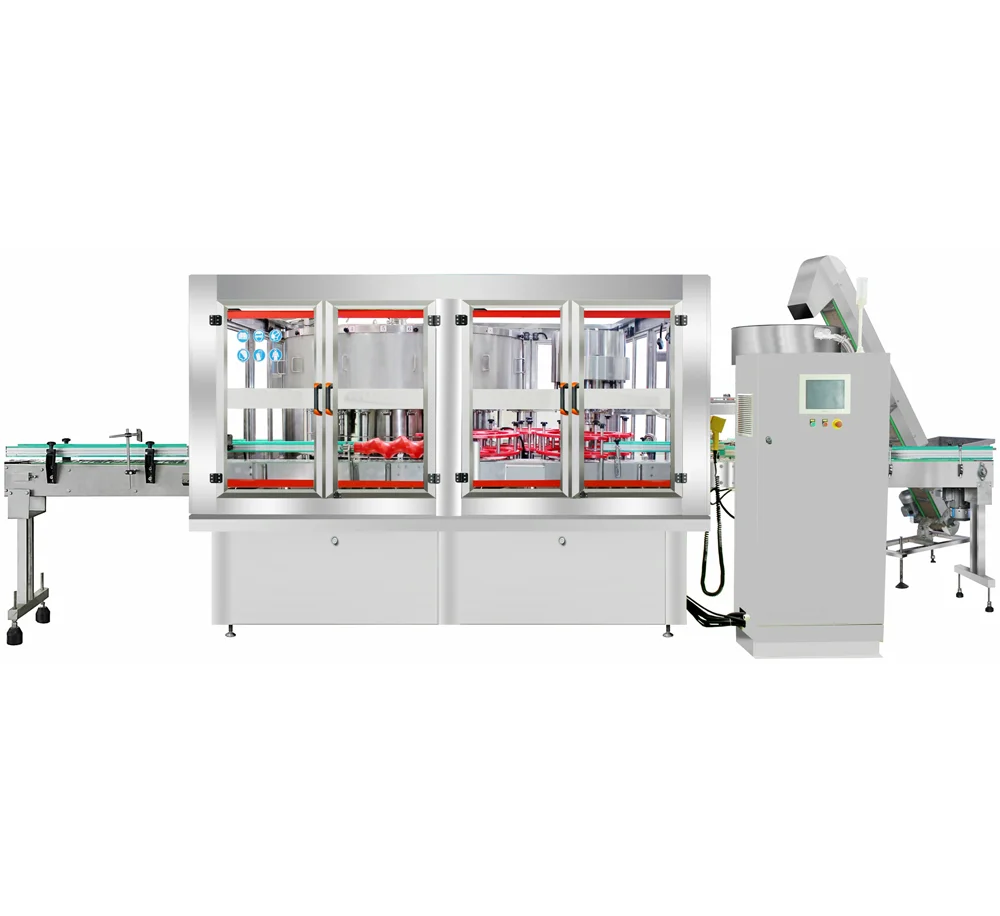

Introducing, the Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine, brought to you by the trusted brand Mars. This innovative machine is designed to efficiently Pasteurize small glass jars of pickles and beer, ensuring a safe and high-quality product every time.

With its compact size, this machine is perfect for small batch producers or home brewers looking to elevate their products. The Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine features a user-friendly interface that allows for easy operation and monitoring of the pasteurization process. Simply load your jars into the tunnel, set the desired parameters, and let the machine do the rest.

One of the key features of this pasteurizing equipment is its ability to maintain a consistent temperature throughout the entire pasteurization process. This ensures that your pickles and beer are pasteurized evenly and thoroughly, resulting in a product that is safe for consumption and has a longer shelf life.

The Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine is also designed with efficiency in mind. Its streamlined design and advanced technology allow for quick pasteurization cycles, maximizing productivity without compromising on quality. This machine is built to last, with durable materials and components that are designed to withstand the rigors of daily use.

Whether you are a small business owner looking to expand your product line or a home-brewer looking to take your hobby to the next level, the Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine from Mars is the perfect solution. With its reliability, efficiency, and ease of use, this machine is sure to be a valuable addition to your production process.

Invest in the Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine from Mars and take your pickling and brewing to new heights. Experience the difference that quality pasteurization can make in your products and elevate your brand to new levels of success. Order yours today and start producing safe, delicious pickles and beer that will keep your customers coming back for more

Small Glass Jar Pickles Beer Tunnel Pasteurizing Equipment Machine

The filling temperature of carbonated drink is 0-4 degree celsius, and the environment temperature is 20-30 degree, so the filled bottles will be full of water drops if they are not warmed, the bottle warming machine warms the bottles by spraying warm water from the nozzles to the outside walls of PET bottles to keep the bottles warm and away from water drops, and and make it convenient for labelling

Features:

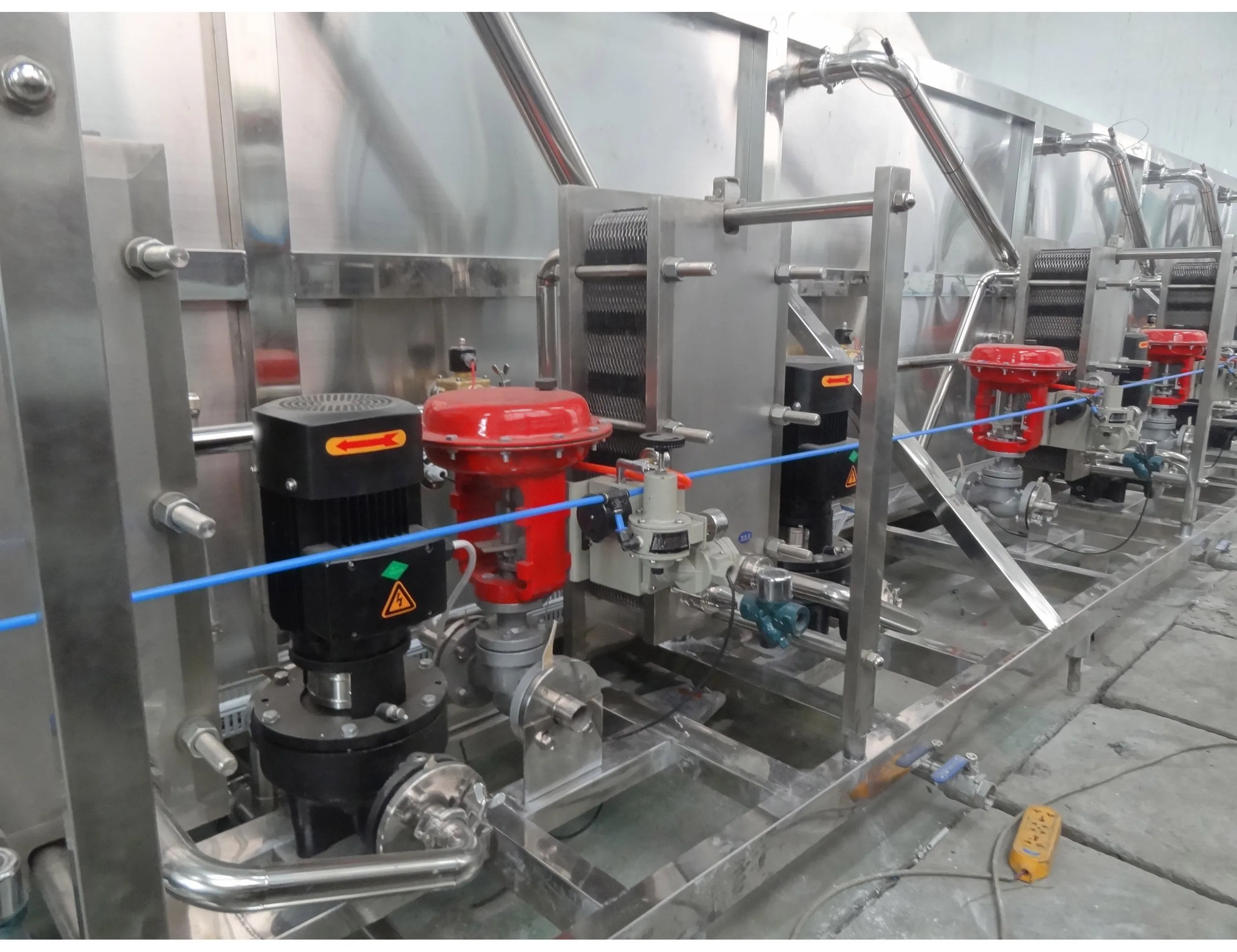

1) The chain plate apply anti-friction and high temperature resistance engineering plastic

2) Apply advanced PLC controller to assure all action precision

3) The conveyor is frequency controlled

4) All spray tubes are made of stainless steel and spray evenly

5) All spray nozzles are made of engineering plastic

6) The catchment flume is made of stainless steel and equipped with a level alarm device

7) The spray-cooling tunnel has a spray cooling recycling water pump

Main Technical Parameter:

Model |

B. SJ.1B-10 |

Rated Capacity |

3000C/H |

Tunnel length |

10M |

Chain width |

1.2M |

Efficient Area |

10m2 |

Main Conveyor Speed |

233.25 mm/minute |

Bottle Entrance Temperature |

5-10°C |

Bottle Exit Temperature |

30-40°C |

Pasteurization Time |

20 minutes |

Total Time From Entrance to Exit |

40 minutes |

Pasteurization Temperature |

62-63°C - can be adjustable |

Overheat Temperature |

≤97°C - can be adjustable |

Max. Height of Bottle |

H≤300mm |

Pasteurization Material |

Water(Pressure:2-4Kgf/cm2), water heating by steam |

Temperature processing area |

8 phases |

Water recycle capacity |

10m3/hour |

Water Consumption |

≤2m3/h |

Steam Pressure |

4-6Kgf/cm2 |

Steam Consumption |

200Kg |

Compressed Air Pressure |

2-4Kgf/cm2 |

Compressed Air Consumption |

5.8m3/h |

Temperature Control |

By PID digital |

Main motor power |

1.1Kw |

Total Power |

17.84 KW |

Dimension Size |

10000*1400*1650MM |

Total Weight |

6000Kg |