- Overview

- Recommended Products

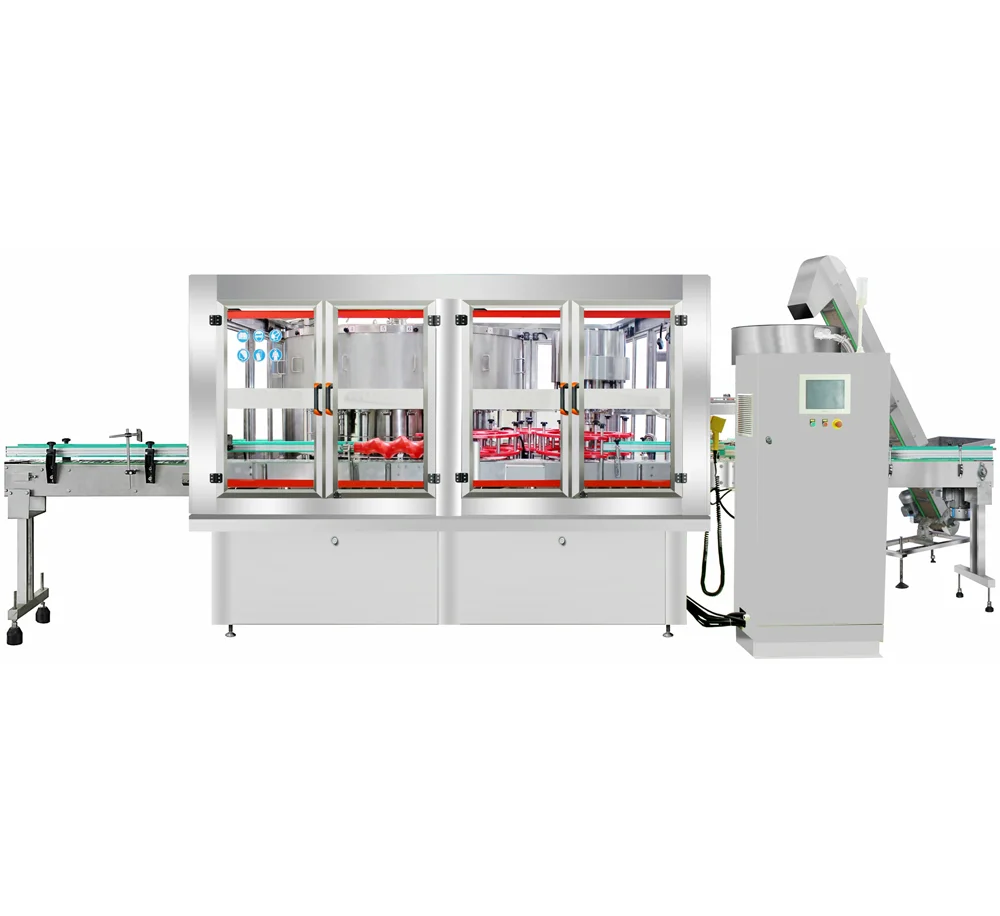

Introducing, the innovative Automatic 5L Plastic Bottle Rotary Edible Oil Weighing Filler Capper from Mars, designed to streamline your oil packaging process with precision and efficiency.

This state-of-the-art filling machine is perfect for businesses looking to automate their production line and increase output. With a high-speed rotary design, it can fill up to 5 liters of edible oil into plastic bottles in a matter of seconds. The built-in weighing system ensures accurate filling every time, so you can have peace of mind knowing that each bottle is filled to the exact desired weight.

The Automatic 5L Plastic Bottle Rotary Edible Oil Weighing Filler Capper is user-friendly and easy to operate, making it ideal for both experienced professionals and newcomers to the industry. The intuitive control panel allows you to adjust settings and monitor the filling process with ease, giving you full control over your production line.

In addition to its filling capabilities, this machine also comes equipped with a capping mechanism that securely seals each bottle with a tight and leak-proof cap. This ensures the freshness and quality of the oil inside, giving your customers a product they can trust.

Durably constructed from high-quality materials, the Mars’s Automatic 5L Plastic Bottle Rotary Edible Oil Weighing Filler Capper is built to last and withstand the demands of a fast-paced production environment. Its compact design saves valuable floor space, making it suitable for small to medium-sized businesses looking to optimize their operations.

The Mars’s Automatic 5L Plastic Bottle Rotary Edible Oil Weighing Filler Capper is a reliable and efficient solution for packaging edible oil. With its high-speed filling, precise weighing, and secure capping capabilities, this machine will help you increase productivity and deliver top-quality products to your customers. Transform your oil packaging process today with this cutting-edge filling machine from Mars

Automatic 5L Plastic Bottle Rotary Edible Oil Weighing Filler Capper

Automatic Oil Bottling Line Palm Vegetable Edible Cooking Oil Plunger Filling Machine

Bottle Material: PET / PE / Glass / Metal

Bottle Type: Round / Square / Unique

Cap : Press cap

Label: Sticker Label / Shrink Label

2 / This machine adopts the weighing filling method

3 / The filling valve adopts a double-stroke cylinder to achieve fast filling followed slow filling double-speed stable, accurate filling to improve filling accuracy.

4 / The valve is able to be closed automatically in time for abnormal conditions to avoid a large loss of oil

5 / The filling valve nozzles has a manual cup cover

Main Refining Processes:

De-mixed, de-gumming, dehydration, de-acidification, de-colorzation, de-waxing and de-odorization.

1. Degumming: Usded to neutralizing, and water washing, to rid off the acid

2. Deodorization: Used to rid off the fetid smell/odour of oil by steam understand of high temperature.

3. Soap feet vessel: Used to refine the oil sediment from oil refiner, to get some oil from oil sediment

4. Hot & Alkali water tank: Used to produce hot water heated by the steams, also alkali water from the alkali dis-voling tank, for adding into the oil refiner

5. Alkali dis-voling tank :Used to produce the alkali water

6. Steam separator: Separating the steam to oil refiner, de-colorer, deodorizer, hot water tank, etc

7. Decoloring vessel: Used to rid off the color of the oil

8. Clay tank:Store the medication de-colored for the clay tank

9. Transfer hot oil furance:Contact to the deodorizer part, producing high temperature (280 degrees or so) for deodorization.

10. Gear pump: Pump oil into kinds of vessel and tank

12. Water pump: Pump cool water into water tank

13. Transfer hot oil pump: Pump hot oil into transfer oil furance

14. Cooling water tower: Cool water for cooling oil, recycling using

15. Dewaxing /winterization / fractional

Technical Parameters

Model |

YGF12-4 |

Filling material |

Edible oil |

Filling volume range |

1000-5000ml |

Production speed |

2000BPH - 1000ml |

Filling heads |

12 |

Capping heads |

4 |

Capping method |

Screw capping |

Suitable bottle diameter(mm) |

50-180 |

Suitable bottle height(mm) |

150-340 |

Spraying pressure(MPa) |

0.25-0.3 |

Total power(Kw) |

5.88 |

Weight(Kg) |

3500 |

Dimension(mm) |

2800*2000*2200 |