- Overview

- Recommended Products

Introducing, the Small Automatic Glass Bottle 3 in 1 Isobaric Beer Filling Crown Capping Machine from Mars - the perfect solution for small breweries looking to efficiently bottle their delicious brews. This compact machine is designed to streamline the bottling process, saving time and ensuring consistent quality with every fill.

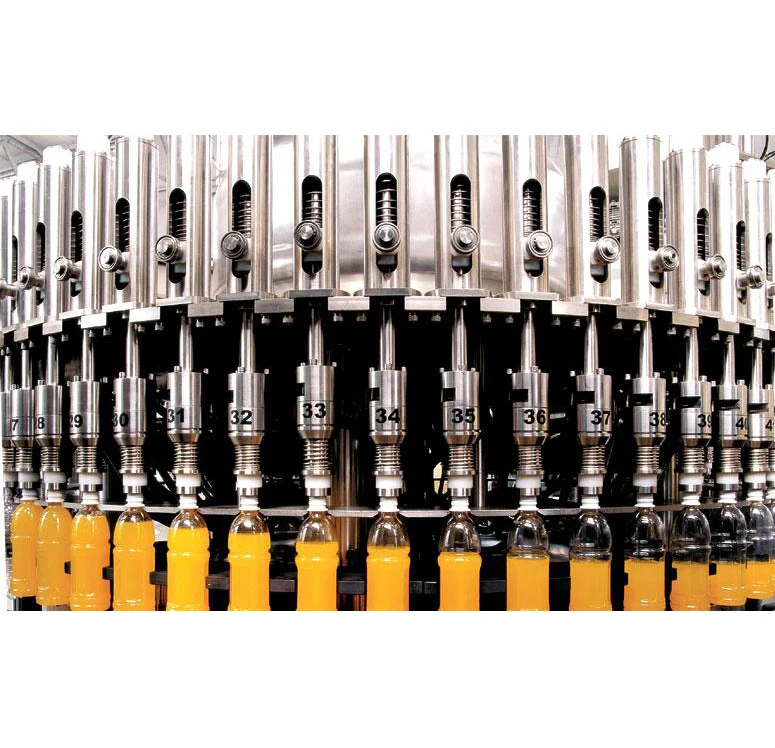

The 3 in 1 design of this machine means that it can handle three key stages of the bottling process in one seamless operation. First, the isobaric filling system ensures that the beer is filled precisely to the desired level without any excess foaming or spillage. This not only ensures a consistent fill level for each bottle but also helps to maintain the beer's carbonation and flavor profiles.

Next, the crown capping mechanism securely caps each bottle, sealing in the freshness and preventing any leaks or spills. The machine is equipped with a reliable capping system that ensures a tight seal on each bottle, so you can be confident that your beer will stay fresh and carbonated until it reaches your customers' hands.

The Small Automatic Glass Bottle 3 in 1 Isobaric Beer Filling Crown Capping Machine is easy to operate, with user-friendly controls that allow you to adjust settings quickly and easily. The machine is also equipped with safety features to protect operators and ensure smooth operation.

This machine is ideal for small breweries looking to increase their bottling capacity without investing in large, expensive equipment. The compact size of the machine makes it easy to fit into tight spaces, and its durable construction ensures long-lasting performance.

Whether you're bottling a batch of your signature IPA or experimenting with a new seasonal release, the Small Automatic Glass Bottle 3 in 1 Isobaric Beer Filling Crown Capping Machine from Mars is a reliable and efficient choice for small breweries. Invest in this machine today and take your bottling process to the next level

Small Automatic Glass Bottle beer filling crown capping machine

Brief Introduction:

Ø Adopting Germany Technology, combining the characteristics of beer production, our company designs and develops this type of beer Rinser filler and capper 3 in 1 machine

Ø This machine has CIP washing function, which can use acid, alkali and hot water for washing filling pipe lines

Ø The whole machine adopts manual dry oil lubricating system, which makes machine maintenance more convenient

Ø The whole machine adopts man and machine interface operation, PLC control

Rinsing Part

Adopting high strength spring type stainless steel bottle rinsing gripper, to ensure the glass bottle smooth turning, washing nozzles are plum flower structure, can rush to the bottom of the bottle and the corner, make the wash more clean

Filling Part

Special long filling valves for beer filling, double de-vacuum

Spring type mechanical device to elevate glass bottles, big bearings to support beer tank above filling valves

The filling machine has the function of closing filling valves when there is broken bottle, and washing away broken bottle. The vent pipe has automatic foam-removing device

It is driven through gears inside the machine frame

Link-wheels in Rinser, filler and capper are transported in ringed support of bottle-neck

Capping Part

Capping part of the machine with highest precision. Stainless steel crown pressing plunger and mechanical mixing type magnet crown Unscrambler ensure crowing clean and secure. Hopper, crown picking, and crown pressing all use magnet transportation. Crowning is secure and it has ability of pressure unloading to reduce the broken bottle rate

Crown distributing groove is equipped with downwards cap pick-out device

Equipped with hot water high pressure foam hitting device to replace air in the bottle, ensure oxygen content less than 0.15mg/L

Model |

BCGF14-12-4 |

Washing heads |

14 |

Filling heads |

12 |

Capping heads |

4 |

Production capacity |

1000-1500B/Hour - 500ml |

Applicable bottles |

Diameter: 50-108mm, height 90-330mm |

Aseptic air consumption |

0.4m3/min - 0.4-0.6Mpa |

Washing water consumption |

1.5m3/h |

Washing water pressure |

2-3 kg/cm2 |

CO2 consumption |

18g/100l |

Rated voltage |

220V/380V |

Control voltage |

24V |

Main motor power |

2.2kw |

Hopper motor power |

0.36kw |

Vacuum pump motor power |

0.75kw |

Overall dimensions |

2150×1780×2350mm - L×W×H |

Total weight |

2500Kg |