- Overview

- Recommended Products

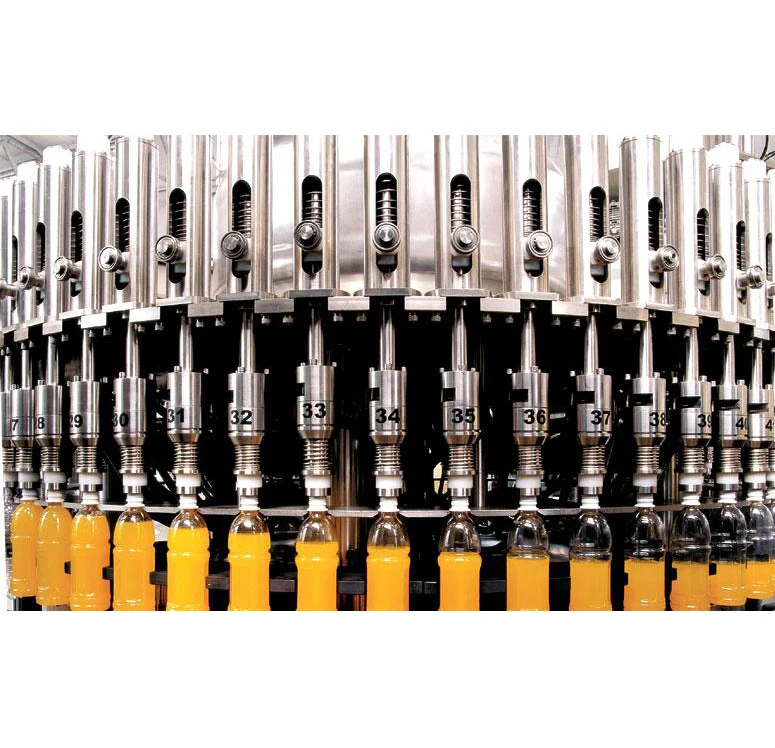

- Specially designed for the full automatic packaging production line of beer, beverage, pure water, fruit juice, dairy products, etc.

- With full automatic functions of bottle transfer and arrange, membrane packing, sealing and cut, shrinkage, cooling and shaping, etc.

- Using advanced constant temperature membrane theat binding technology in the world with clear and secure seal.

- The quick seal cooling structure guarantee that the seal has higher strength even if under high speed production condition.

- Adopt with PLC automatic program circulation control with stable and reliable performance.

- The original imported guide bar cylinder guarantee correct operation and durable.

- The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss.

- All the transfer system is controlled by frequency changing devices with stable and smooth transfer speed.

- Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect.

- 3 layers of heat insulation treatment with good insulting property, quick temperature rise and energy saving.

- The enhanced cooling shaping passage can quickly turn the packing membrane into high strength status that is conveniently stored and transported.

- It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine.

- Conveyor height and bottle inlet direction, size: according to customer request

- Equipment safety reach to standard requirement.

Characteristic:

Main Technical Parameter:

Model |

SP-20 |

Packing speed |

15-20Packages/Min |

Suitable bottle material |

glass bottle, pop-top can, PET bottle and material which can bear 200℃ |

Suitable bottle specification |

bottle diameter: Φ60-120Φmm Bottle height: ≤340mm |

Packing material |

PE Hot shrink film thickness: 0.03-0.10mm max. film width: 600mm |

Packing method |

two sides sealing while two sides open |

Working pressure |

≥0.6Mpa(dry air) |

Gas consumption |

25mP3P/H |

Suitable voltage |

3 phase, 380V/50Hz |

Power: |

28Kw |

Weight |

1500Kg |

Main Parts Origin:

No. |

Parts name |

Model |

Qty |

Brand |

1 |

PLC |

XC3-32T-E |

1 |

SIEMENS |

2 |

Touch screen |

TP560-L |

1 |

SIEMENS |

3 |

Inverter |

3 phase, 0.75KW |

1 |

TECO,TAIWAN |

4 |

Contactor |

3TB40 |

4 |

SCHNEIDER |

5 |

Electric door lock |

3TB44 |

1 |

SIEMENS |

6 |

Thermo relay |

1.8A |

3 |

SCHNEIDER |

7 |

SSR |

SAP 4020D |

1 |

DONGQI,HONGKONG |

8 |

Temperature control instrument |

TE7-RB10 |

1 |

DONGQI,HONGKONG |

9 |

Motor |

|

|

SIEMENSE BEIDE |

10 |

Pneumatic parts |

|

|

AIR TAC |

11 |

Intermediate relay |

HH52P 24VDC |

2 |

AUTONICS |

12 |

Proximity switch |

PR12-4DN |

4 |

AUTONICS |

13 |

Photo electricity switch |

BR100-DDT |

1 |

AUTONICS |

14 |

Magnetic switch |

CS1-F |

5 |

AIRTAC |

15 |

photoelectric cell |

ZT-1200N |

1 |

OPTEX FA |

16 |

Mirror photo electricity |

BM1M-MDT |

1 |

AUTONICS |

17 |

AIR SWITCH |

DZ47 C6 2P |

3 |

DELIXI |

18 |

Alarm light |

YT703 |

1 |

|

19 |

Switch power |

HS-350-24 |

1 |

TAIWAN |