- Overview

- Recommended Products

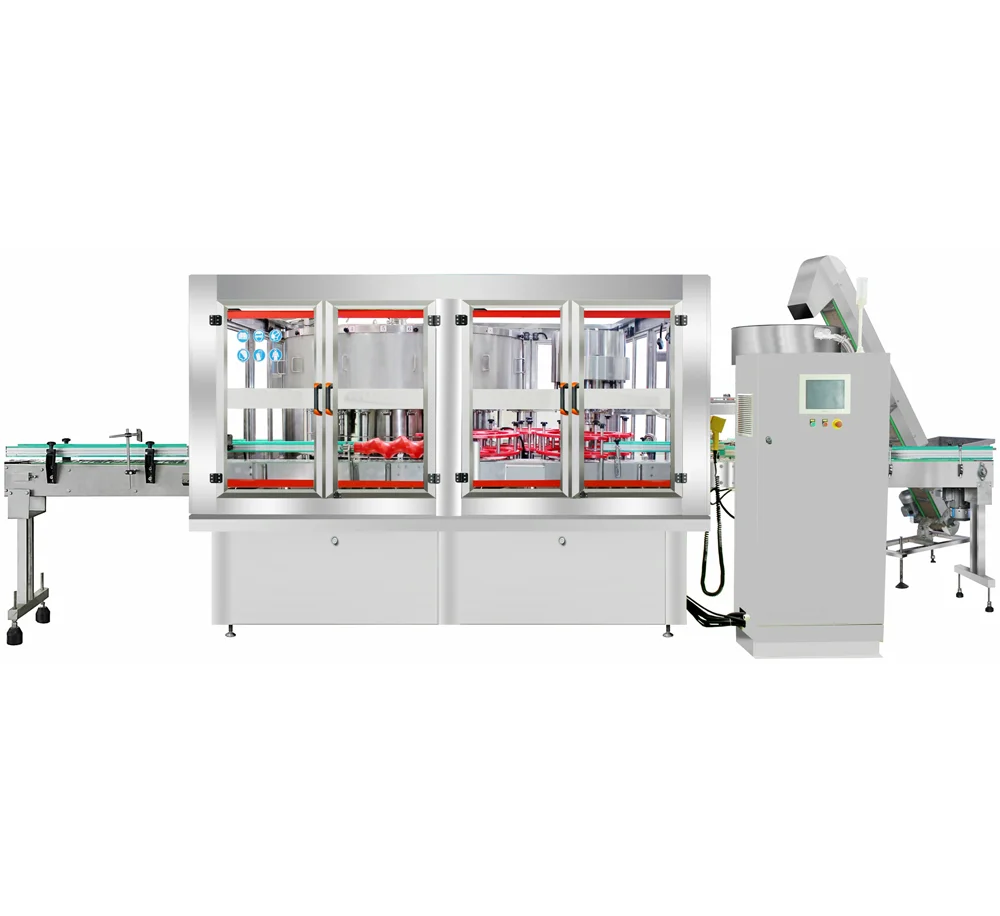

Introducing, the Mars’s Semi-Automatic Vacuum Tinplate Can Sealing Machine, the perfect solution for sealing your tinplate cans with ease and efficiency. This highly reliable and user-friendly machine is designed to streamline your packaging process and ensure a secure seal every time.

With its innovative semi-automatic operation, this sealing machine is perfect for small to medium-sized production runs. The machine is equipped with a vacuum system that removes excess air from the cans before sealing, ensuring a tight and long-lasting seal that preserves the freshness of your products.

The Mars’s Semi-Automatic Vacuum Tinplate Can Sealing Machine is suitable for sealing a wide range of tinplate cans, making it versatile and adaptable to your specific packaging needs. Whether you are sealing cans of food, beverages, or other products, this machine is up to the task.

Designed with user convenience in mind, this sealing machine is easy to operate and maintain. The intuitive controls and simple settings make it easy to adjust the sealing process to achieve the perfect seal every time. Additionally, the machine is constructed with durable materials that are built to last, ensuring reliable performance and minimal downtime.

In addition to its sealing capabilities, the Mars’s Semi-Automatic Vacuum Tinplate Can Sealing Machine also offers a compact design that saves valuable space in your production area. The machine is easy to move and set up, allowing you to maximize efficiency and productivity in your packaging operation.

For a dependable and efficient sealing solution, look no further than the Mars’s Semi-Automatic Vacuum Tinplate Can Sealing Machine. With its high-quality construction, user-friendly design, and versatile capabilities, this machine is an essential addition to any packaging operation.

Upgrade your packaging process with the Mars’s Semi-Automatic Vacuum Tinplate Can Sealing Machine and experience the difference in quality and efficiency

Semi- Automatic Vacuum Tinplate Can Sealing Machine

Selling point

1. This equipment is suitable for all kinds of round opening tinplate cans, aluminum cans, plastic cans, paper cans packaging products first vacuum and then fill nitrogen, and finally seal. Effectively extend the shelf life of products, is the ideal equipment for food, beverage, pharmaceutical and other industries

2. The working mode of single head and single room is simple to operate

3. The tank body does not rotate during the sealing process, which is safe and stable, especially suitable for fragile and liquid products.

4. Sealing wheel and indenter are made of Cr12 die steel, durable and high sealing degree.

5. Oxygen residual less than 3%, effectively extend the shelf life of products, improve product quality

Product parameters:

1 |

Model |

ZBFG-1 |

2 |

Sealing head |

1 |

3 |

Number of sealing wheels |

2 - 1 first sealing wheel, 1 second sealing wheel |

4 |

Sealing speed |

4-8 cans/min - related to the size of the jar |

5 |

Sealing height |

25-220mm |

6 |

Sealing diameter |

35-130mm |

7 |

Working temperature |

0 ~ 45℃, working humidity: 35 ~ 85% |

8 |

Working power supply |

single-phase AC220V 50/60Hz |

9 |

Total power |

2.6Kw |

10 |

Weight |

330KG - approximate |

11 |

Dimensions |

length 780* width 980* height 1450mm |

12 |

Working air pressure - compressed air |

≥0.6MPa |

13 |

Air consumption - compressed air |

About 60L/min |

14 |

Nitrogen source air pressure |

≥0.2MPa |

15 |

Nitrogen consumption |

About 50L/min |

16 |

Minimum vacuum pressure |

-0.07MPa |

17 |

Residual oxygen |

< 3% |

|

Open cam instead of index gear box to divide the steps Compare with index gear box: Open cam Advantage: Can be see by sight, Easy maintenance, Easy oil Easy replace bearing if have problem

Shortage: opened, if drop objects or tools maybe damage the cam and bearing Oil and clean is important |

|

|

Quality Gears and axis keep the machine stable and reliable | |

|

PLC and program control the machine

Intelligent program control all steps Easy operate and control Any fault auto stop and indicate

With advanced Encoder drive, keep machine more efficient, reliable

|

|