- Overview

- Recommended Products

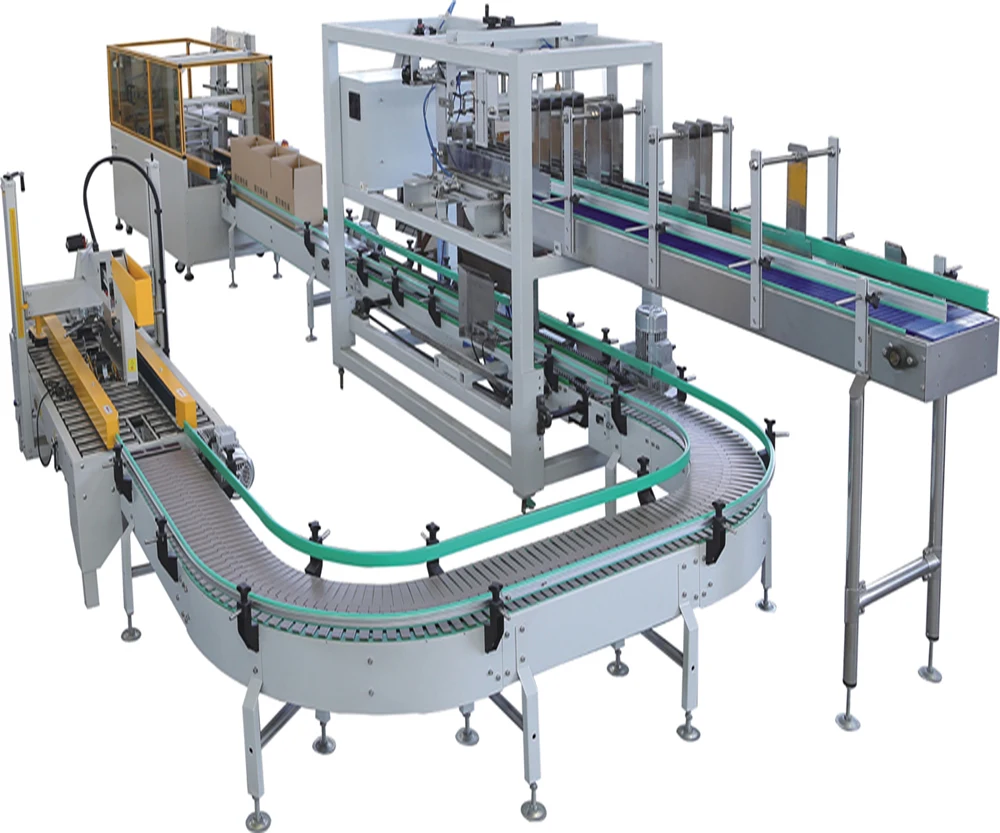

Introducing, the Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System, the perfect solution for clean and healthy drinking water in your home or office. This innovative system uses advanced reverse osmosis technology to remove impurities and contaminants from your tap water, giving you peace of mind knowing that your water is safe and clean.

The Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System is designed to be compact and space-saving, making it easy to install and fit into any kitchen or workspace. The sleek stainless steel design not only looks great, but is also durable and long-lasting, ensuring years of reliable performance.

With a powerful filtration system, this water purification treatment system is capable of removing up to 99% of common contaminants such as lead, chlorine, fluoride, and bacteria, giving you cleaner and more refreshing water to drink. The system also helps to improve the taste and odor of your water, making it more enjoyable to drink.

Easy to use and maintain, the Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System features simple controls and a user-friendly interface. The system is also equipped with a convenient filter change indicator, so you'll always know when it's time to replace the filters to ensure optimal performance.

Whether you're looking to improve the quality of your drinking water or simply want a more convenient and sustainable solution, the Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System is the perfect choice. Say goodbye to bottled water and hello to clean, great-tasting water right from your tap.

Trust the Mars brand for quality and innovation when it comes to water purification systems. With the Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System, you can enjoy the benefits of clean and healthy water with ease and convenience. Upgrade your water quality today with the Mars’s Stainless Steel Compact Reverse Osmosis Water Purification Treatment System

Reverse Osmosis is adopted almost in all industries, including water desalting( make drink water from bitter &salt water and seawater), purified water (purification of cooling water and boiler water), ultra-pure water (water for paint illuvial and semiconductor), water for chemical manufacturing (pharmaceutical or cosmetics industries), foods and beverage production (produce concentrating fruit juices and cheese) and purification of industry waste water(purification of waste water etc. RO technique is easy to operate, which has high efficiency of desalination. With the high ability of removing heat, with the economic affection, it is perfect equipment for pharmaceutical industry

EDI is electro deionization. The EDI design combines two well-established water purification techniques electro dialysis and ion-exchange resin deionization. Through this revolutionary technique, dissolved salts can be removed with low energy cost and without the need for chemical regeneration

Working principle for Osmosis Reverse System

Osmosis is a process of water from the dilute solution automatically flowing to concentrate side through the semi permeable membrane

RO is the opposite process of the natural permeation. It is caused by pile pressure on the concentrate solution, which is contacted with the semi permeable membrane. If the applied pressure is bigger than the natural osmosis pressure, the solution will pass through semi permeable membrane

Then the diluted solution is formed at the opposite side. Meanwhile the concentrate solution will be formed at the applied pressure side. If the applied pressure is equal to the natural osmosis pressure of solution, the solution can not flow to the opposite side. If the applied pressure is smaller than the natural osmosis pressure of solution, the solution will flow from the diluted side to the concentrate side

Speed of water passing membrane is related with membrane capability, solution temperature. It is also related to the value------pressure difference of membranes both sides subtracts osmosis pressure difference of diluted and concentrated solution

The osmosis pressure has direct relationship with density and temperature of solution. It is also related with the type of ion in solution

There is the principle for the pressure difference: the solution with the density of per 1000mg/L, which is contained sodium chloride, at room temperature, the osmosis pressure value is 0.069Mpa

Techniques for Osmosis Reverse System

RO system normally includes pre-treatment and mainframe and assistant equipment, but assistant equipment is not necessary.

Simple pre-treatment crafts include multi-layer bed filter, softener or anti-incrustant dosing station and ultra-filter

The completed pre-treatment crafts include Floculant dosing station, multi-layer bed filter, active carbon filter, softener or anti-incrustant dosing station, heat exchanger, ultra-filter and PH value adjusting equipment

The assistant equipment is the recycling chemical sterilizing cleaning equipment

EDI modules continually produce ultra-pure water up to 18.2 MΩ/cm. EDI also can be run continuously or intermittently

Electropure EDI removes ions from water by forcing them out of the feed stream into adjacent streams via an electric potential. EDI is different from ED by using resins in the diluting chambers the resins allow for more efficient migration of ions in very low conductivity water. The resins operate in steady status, they act not as an ion reservoir but as an ion conduit

Advantages of EDI for Osmosis Reverse System

EDI no need chemical regeneration

No need storage of acid and alkali, dilution and transportation settings

Having no settings to deal with regenerating dirty water and dirty water

Saving water for back purge and cleaning. High producing ability for ultra-pure water

No need stop the machine at the time of regenerating EDI

Providing table quality of water

Low dissipation energy

Easy to operate and manage, having small labor intensity

Easy to install, running. The maintenance charges are low

EDI removes ions from aqueous streams, typically in conjunction with reverse osmosis and other purification devices.

1 stage RO+EDI

Double stages RO +EDI

Double stages RO +EDI+Ultra-filterIt - It can satisfied the WFI requirement in Pharmacopoeia in partial countries, so it is needn't use multi-effect water distiller

Equipment characteristics for Osmosis Reverse System :

Manufacture time: It is a company with redundant experiences, who produces water system equipment earlier than others

Control way: Normal one: PLC + touch screen + paperless recorder or printer full automatic control. It also can be customized according to customers requirements. It can realize the alarm of level, conductivity etc by PLC, it is also can observe the online value of temperature, pressure, conductivity, flow etc

Linkage: it can be customized to realize the linkage of equipment and storage tanks, according to the customers requirements

Cost budget: It is designed equipment and made cost budget according to the customers requirements

Producing advantages:

Advanced welding machine.

Advanced welding technology.

Advanced surface treatment.

Using primitive plate to process tube plate and flange.

Using the North Sea capped end

Using X-Ray crack detection to check interior quality

Using endoscope to check the welding quality

Using roughness detector to check the quality of polish

Using mechanical and electro-chemical polish, acid clean, passivation - critical parts

Item |

Component |

1 |

American HYDRANAUTCS company’s ESPAI high technology 80P×40 compound film |

2 |

Stainless steel high pressure film shell |

3 |

Reverse osmosis high pressure pump |

4 |

All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system |

5 |

Online type pressure auto self-protection device |

6 |

Online type electricity indicator - with stable compensation |

7 |

PLC control system- JAPANESE MITSUBISHI |

8 |

System safe protecting and alarm system |

9 |

System frame |

10 |

Working process demonstrator |