- Overview

- Recommended Products

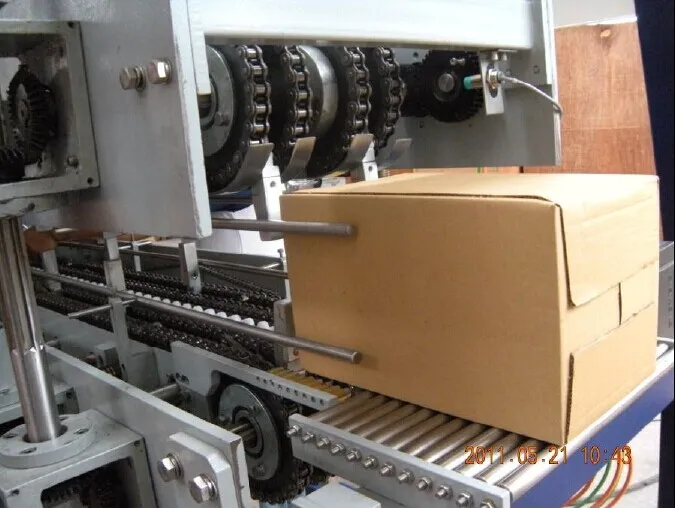

Introducing the innovative Automatic Wraparound Hot Glue Sealing Case Packer by Mars! This cutting-edge packaging machine is designed to streamline the packaging process and increase efficiency in your production line.

The Automatic Wraparound Hot Glue Sealing Case Packer is perfect for businesses looking to automate their packaging operations. With its advanced technology and user-friendly interface, it is easy to set up and operate, saving you time and manpower.

This case packer is equipped with a hot glue sealing system that ensures a secure seal on every package. The hot glue ensures that your products are fully protected during transit, reducing the risk of damage and increasing customer satisfaction.

One of the standout features of this machine is its wraparound design, which allows for seamless packaging of products. The wraparound feature ensures that each package is securely sealed and protected, giving you peace of mind that your products will arrive at their destination in perfect condition.

In addition to its superior sealing capabilities, the Automatic Wraparound Hot Glue Sealing Case Packer is also highly versatile. It can handle a wide range of packaging sizes and shapes, making it ideal for businesses with diverse product lines.

The Mars brand is known for its high-quality, reliable packaging solutions, and the Automatic Wraparound Hot Glue Sealing Case Packer is no exception. Built to last, this machine is constructed from durable materials that can withstand the rigors of daily use in a busy production environment.

The Automatic Wraparound Hot Glue Sealing Case Packer by Mars is a must-have for businesses looking to improve their packaging processes. With its advanced features, user-friendly interface, and superior sealing capabilities, this machine will revolutionize the way you package your products. Invest in the Automatic Wraparound Hot Glue Sealing Case Packer today and experience the difference it can make in your business operations

Automatic Wraparound Hot Glue Sealing Case Packer

The machine adopt to servo location, PLC controlling, auto operation, main drive adopt to import motor drive, multi degree rotation via chain, chain wheel speed regulator etc. Its auto degree is high, reliable controlling, easy to adjust, intelligent manipulation etc advantage, can widely used for beverage, beer, chemistry, food, medicine ect industry, can do all kind of tin and bottle second time package, can match with auto filling production line

1. Main Technical Parameter

Product capacity |

15cartos/ minute |

Package product overall size |

Length 350-450, Width 230-330mm, Height:85-320mm |

Bottle entry conveyor size |

L3000*W620*1200MM |

Package bottle diameter |

55-108MM |

Cardboard requirement |

Accord with international GB/T6544-2008 |

Compressor air |

1500L/minute, 0.6-0.8Mpa |

Rating power |

15Kw |

Power supply |

3 phase, 380V, 50HZ |

Controlling power supply |

24V DC |

Hot melting glue solidify time |

1.5-2Seconds |

Machine weight |

4000kg |

Overall size |

L6285*W2582*H2115MM |

2. Facility basic summary and requirement:

Facility name |

Carton package machine |

Power supply |

380V, three-phase |

Production capacity |

15 pack/ minute |

Power supply |

220V AC |

|

Product package qualified ratio |

>99.8% |

Controlling voltage |

24V DC |

Hot glue solidify time |

≤1.5-2S |

Main machine power |

15KW |

Facility weight |

4T |

Gas consumption quantity |

1500 L/min |

Machine overall size |

6285*2582*2115 |

Compressor air requirement |

0.6~0.8MPa |

Bottle enter size |

3000*620*1200 |

Package product overall size |

350-450 Lengt/ - 200-330 Width/b - 85-320 Heightmm |

noise |

85dB |

Circumstance temperature requirement |

0—45℃ |

|

Circumstance humidity requirement |

Usually below 75%RH |

Workshop requirement condition |

Firm foundation

|

|

Facility collocate requirement |

Dry, anti-dust, good ventilation good condition |

||

|

Cardboard specific requirement |

A. Material: Corrugate, used carton is three-layer, surface is white 250gram/sm middle is high strength 150gram/sm. Bottom is cow cardboard 280g/sm; B. carton each layer not allow have layering phenomenon, Leatheroid thickness ≥3mm C. carton indentation thread thickness is moderate, width is not bigger than 2mm |

||

3. Applied bottle type: round bottle, square bottle, alien bottle

Package product |

Package specification |

Capacity |

Applied bottle type |

200ML-400ML |

4*6,4*5,3*4or 3*5, 2*3 etc |

15carton/minute |

PET/Tin/Glass bottle |

300ML-500ML |

4*6,4*5,3*4 or 3*5, 2*3 etc |

15carton/minute |

PET/Tin/Glass bottle |

300ML-600ML |

4*6,4*5,3*4 or 3*5, 2*3 etc |

15carton/minute |

PET/Tin/Glass bottle |

500ML-1250ML |

3*4, 2*3 etc |

15carton/minute |

PET/Tin/Glass bottle |

1250ML-2500ML |

2*3, 2*2 etc |

15carton/minute |

PET/Tin/Glass bottle |

Product show