- Overview

- Recommended Products

Introducing, the Mars’s Automatic 330ml 500ml Glass Bottle Ginger Beer Filling Capping and Labeling Machine, a top-of-the-line solution for efficiently filling, capping, and labeling your delicious ginger beer in glass bottles. This innovative machine combines cutting-edge technology with user-friendly design to streamline your production process and increase productivity.

The Mars’s Automatic Filling Capping and Labeling Machine is designed to accommodate both 330ml and 500ml glass bottles, making it versatile for different volumes of ginger beer. The automatic filling system ensures precise and consistent filling of each bottle, minimizing waste and maximizing efficiency. With a capacity to process up to 3000 bottles per hour, this machine is perfect for small to medium-sized beverage production facilities.

In addition to filling, the Mars machine also features a high-speed capping system that securely seals each bottle with a reliable and airtight cap. The capping process is fully automated, reducing the risk of human error and ensuring a consistent finish on every bottle. This machine is equipped with advanced sensors and controls to monitor the capping process and adjust as needed to maintain optimal performance.

The Mars’s Automatic Filling Capping and Labeling Machine also includes a state-of-the-art labeling system that can apply custom labels to each bottle with precision and speed. The labeling process is seamlessly integrated into the overall operation of the machine, eliminating the need for separate labeling equipment and streamlining your production line.

With its compact design and user-friendly interface, the Mars’s Automatic Filling Capping and Labeling Machine is easy to set up and operate. The machine is constructed with high-quality materials and components to ensure durability and longevity, making it a reliable investment for your beverage production needs.

Upgrade your ginger beer production process with the Mars’s Automatic 330ml 500ml Glass Bottle Ginger Beer Filling Capping and Labeling Machine. With its efficient performance, versatile design, and user-friendly operation, this machine is the perfect solution for increasing your productivity and improving the quality of your products. Experience the Mars difference in beverage production technology today

Automatic Glass Bottle Ginger beer filling capping and labeling machine

Brief Introduction:

Ø Adopting Germany Technology, combining the characteristics of beer production, our company designs and develops this type of beer Rinser filler and capper 3 in 1 machine

Ø This machine has CIP washing function, which can use acid, alkali and hot water for washing filling pipe lines

Ø The whole machine adopts manual dry oil lubricating system, which makes machine maintenance more convenient

Ø The whole machine adopts man and machine interface operation, PLC control

Rinsing Part

Adopting high strength spring type stainless steel bottle rinsing gripper, to ensure the glass bottle smooth turning, washing nozzles are plum flower structure, can rush to the bottom of the bottle and the corner, make the wash more clean

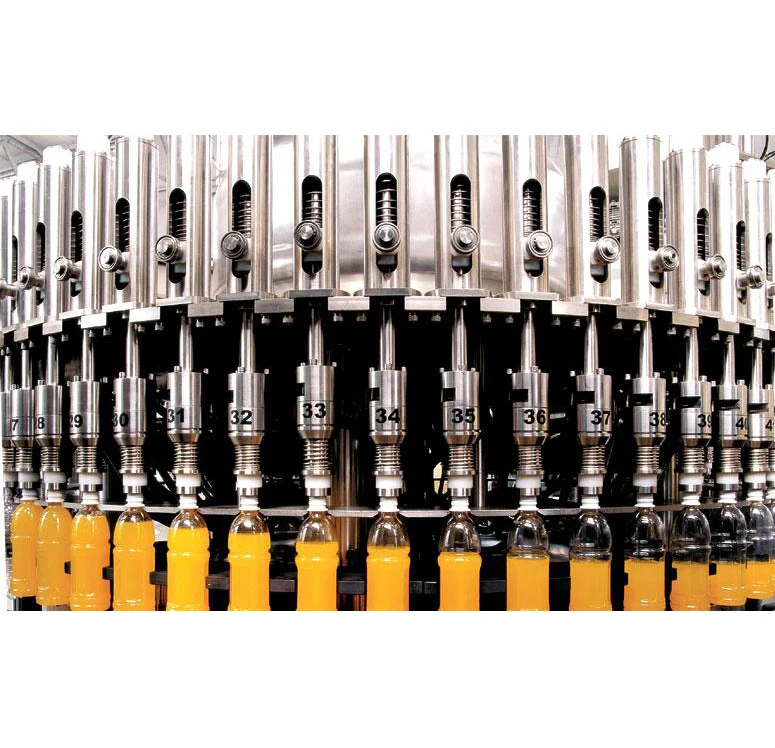

Filling Part

Special long filling valves for beer filling, double de-vacuum

Spring type mechanical device to elevate glass bottles, big bearings to support beer tank above filling valves

The filling machine has the function of closing filling valves when there is broken bottle, and washing away broken bottle The vent pipe has automatic foam-removing device

It is driven through gears inside the machine frame

Link-wheels in Rinser, filler and capper are transported in ringed support of bottle-neck

Capping Part

Capping part of the machine with highest precision. Stainless steel crown pressing plunger and mechanical mixing type magnet crown unscrambler ensure crowing clean and secure. Hopper, crown picking, and crown pressing all use magnet transportation. Crowning is secure and it has ability of pressure unloading to reduce the broken bottle rate

Crown distributing groove is equipped with downwards cap pick-out device

Equipped with hot water high pressure foam hitting device to replace air in the bottle, ensure oxygen content less than 0.15mg/L

Technical Parameters:

BCGF24-24-6 |

|

Washing heads |

24 |

Filling heads |

24 |

Capping heads |

6 |

Production capacity |

4000-5000B/Hour - 500ml |

Applicable bottles |

Diameter: 50-108mm, height 90-330mm |

Aseptic air consumption |

0.4m3/min - 0.4~0.6Mpa |

Washing water consumption |

1.5m3/h |

Washing water pressure |

2~3 kg/cm2 |

CO2 consumption |

18g/100l |

Rated voltage |

220V/380V |

Control voltage |

24V |

Main motor power |

2.2kw |

Hopper motor power |

0.36kw |

Vacuum pump motor power |

2.2kw |

Overall dimensions |

2750×2180×2350mm - L×W×H |

Total weight |

5500Kg |