- Overview

- Recommended Products

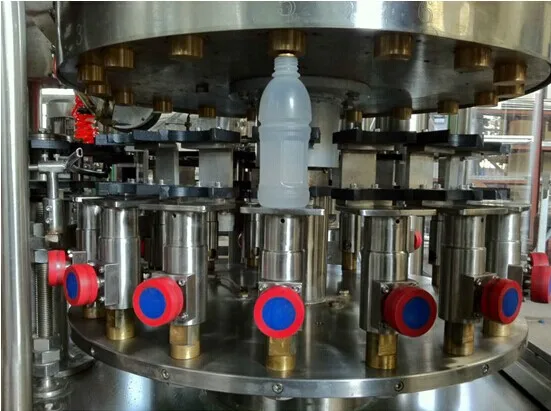

Introducing, the Mars’s Milk Bottle Filling and Sealing Machine Line Price! This top-of-the-line product is perfect for businesses looking to streamline their milk bottling process.

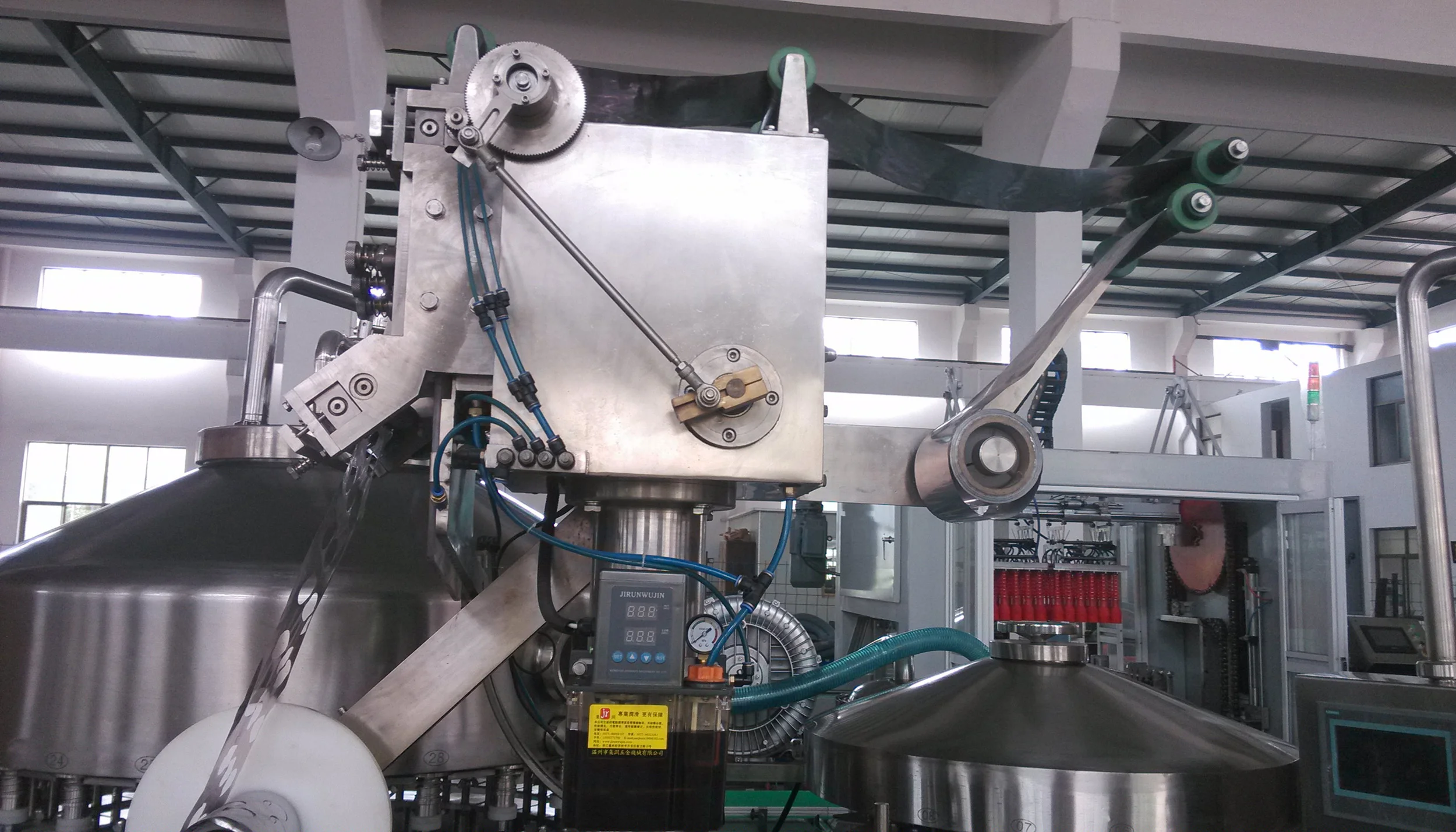

The Mars Milk Bottle Filling and Sealing Machine Line Price is designed to be user-friendly and efficient. With its easy-to-use controls, operators can quickly set up and start filling bottles with ease. The machine is also equipped with a reliable sealing system, ensuring that each bottle is securely sealed for freshness.

This machine is built to last, with a durable construction that can withstand the demands of a busy production environment. The Mars’s Milk Bottle Filling and Sealing Machine Line Price is also easy to clean and maintain, making it a practical choice for businesses looking to minimize downtime.

With its high-speed filling capabilities, this machine is perfect for businesses looking to increase their milk bottling capacity. The Mars’s Milk Bottle Filling and Sealing Machine Line Price can fill and seal bottles at an impressive rate, saving time and labor costs.

In addition to its performance, the Mars’s Milk Bottle Filling and Sealing Machine Line Price is also competitively priced. Businesses can enjoy the benefits of this machine without breaking the bank. This makes it an excellent investment for businesses looking to improve their milk bottling process.

When you choose the Mars’s Milk Bottle Filling and Sealing Machine Line Price, you are choosing a quality product from a trusted brand. Mars has a reputation for manufacturing high-quality equipment that meets the needs of businesses in various industries. With the Mars Milk Bottle Filling and Sealing Machine Line Price, you can trust that you are getting a reliable and efficient machine that will help you streamline your milk bottling process.

The Mars’s Milk Bottle Filling and Sealing Machine Line Price is a practical and cost-effective solution for businesses looking to improve their milk bottling process. With its high-speed filling capabilities, reliable sealing system, and competitive pricing, this machine is sure to be a valuable addition to any production line. Choose the Mars’s Milk Bottle Filling and Sealing Machine Line Price for all your milk bottling needs

Milk Bottle Filling and sealing Machine Line Price

This Milk processing line produce several types of market milk products, such as whole milk, skimmed milk and standardized milk of various fat contents

This Milk processing line raw milk can be fresh milk or powder milk, the procedure method can be pasteurization or HTST Pasteurizer or UHT processing

End product package of this Milk processing line can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box, pre-pak pouches, Tetra pak etc.

Milk Bottle FIlling Machine

| Equipment list of 25T/D DAIRY PRODUCTION LINE - Pasteurized milk\yogurt\cheese\cream\butter | ||

| NO | NAME | MAIN TECHNOLOGY PARAMETER |

| 1 | MILK RECEIVE\STORAGE\AND CREAM SEPARETOR UNIT | |

| 2 | Electron pound scale | Maximum weighing 500KG |

| 3 | Milk weighing tank | Made of SUS stainless steal, single layer, product Feeded in through 40 mesh filter net, CIP cleaning ball |

| 4 | Milk acceptor | SUS304 stainless steel, single layer, CIP cleaning ball |

| 5 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 6 | Twin piping filter | SUS304 stainless steel, two pipe, Stainless Steal Filter Element 100 Mesh |

| 7 | Dish separator | Auto residue discharge |

| 8 | Chiling tank | SUS304 stainless steel, alveolate jacket, attached with compressor |

| 9 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 10 | PREPARING UNIT | |

| 11 | Blending tank | SUS304 stainless steel, heat insulated, top off- center Votical agitator, conical head, air tight man hole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| 12 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 13 | Mini set of plate-type heat exchanger | SUS304 stainless steel, two stages |

| 14 | High speed emulsification tank | SUS304 stainless steel, heat insulated, bottom high speed emulsifier, digital readout thermometer, supporters with adjustable feet |

| 15 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 16 | Twin piping filter | SUS304 stainless steel, two pipe, Stainless Steal Filter Element 100 Mesh |

| 17 | Sterilizing, homogenizing unit | |

| 18 | UHT sterilizer | Tub-type, Sterilzing temperature 137 C, holding time 4S, full automatic control |

| 19 | High pressure homogenizer | 40MPa - starting box included |

| 20 | Temperature holding | SUS304, holding 300S |

| 21 | Distributing plate | SUS304, 3 holes |

| 22 | Cheese\butter processing unit | |

| 23 | Bufferying tank | SUS304 stainless steel, heat insulated, top off- center Votical agitator, conical head, air tight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| 24 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 25 | Cream seperator | |

| 26 | Bufferying container | SUS304, with cover |

| 27 | Milk pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 28 | Butter-churner | SUS304, step less timing |

| 29 | Cheese vat | SUS304, with heating jacket and incising device |

| 30 | Pressor | SUS304, 6 heads |

| 31 | Mould | SUS304, 10L, with cover |

| 32 | Yogurt fermentation unit | |

| 33 | Fermentation tank | SUS304 stainless steel, heat insulated, top off- center Votical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| 34 | Rotary pump | SUS304 stainless steel, Hard Alloy Mechanical Seal, manual step less shift |

| 35 | Plate cooler | SUS304, single stage, milk discharge at 4C |

| 36 | Rotary pump | SUS304 stainless steel, Hard Alloy Mechanical Seal, manual step less shift |

| 37 | Filling unit | |

| 38 | Higher position tank | SUS304 stainless steel, heat insulated, top off- center Votical agitator, conical head, airtight manhole, breather valve, digital readout thermometer, anti-eddy baffle, supporters with adjustable feet |

| 39 | Pasteurized milk filling machine | |

| 40 | Yogurt filling machine | |

| 41 | CIP system | |

| 42 | Semi-auto CIP system | Outer coat of SUS304 stainless steel material, inner shell of SUS316, single cleaning way, Concentrated acid/alcali tank adding system based on US technology, 100L×2 acid/alcali Concentrate tanks |

| 43 | CIP return pump | SUS304 stainless steel, pump lift 24M, Hard Alloy Mechanical Seal, Inner Shell Bright-Polished |

| 44 | installation part | Whole milk processing line installation and commissioning |