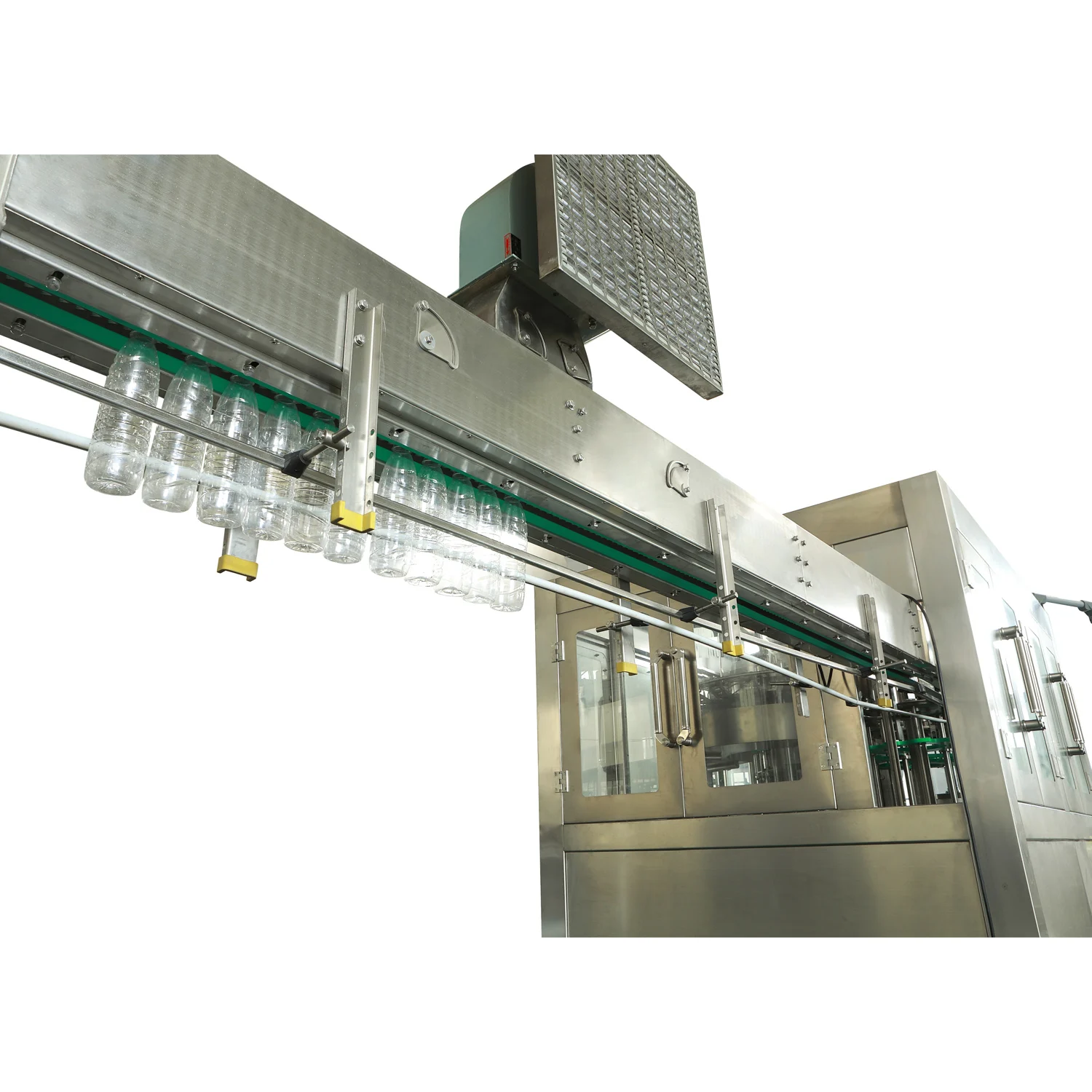

Mars provides high quality bottle filling machines and capping machines which allow for a rapid production flow. These devices are intended for the automatic filling of fluids in bottles or containers with different sizes (bottles, jars, cans), and they find application in fields where liquids need to be bottled or packaged - beverages, detergents, pharmaceuticals. Filling and capping is combined into one in this machine, saving time and leading to cost-effective operations that are correct every single time. Click here to learn more about packaging materials. Filling machines

bottle filling and capping machines In addition, bottle filling and capping apparatuses provide a high degree of precision and accuracy in the filling and capping operation. This is important, particularly when you're using liquids that need to be measured out in specific quantities or when you're dealing with items that should be sealed up flat to keep them fresh and protected. The machines are programmable to fill each bottle with a precise amount of liquid and then cap it tightly, resulting in consistent quality for every item. Click here to learn more about filling machines.

Mars Provide various types high quality filling equipment for your different application. When you're operating a small startup operation or a large scaling up to the production facility, Mars Packaging is your go-to for bottle filling and capping machines. Our machinery can be used for various purposes, and most of this equipment is changeable, resulting in the ability to easily adjust it to fit your production line needs. And, of course, we provide adjustable torque settings on all of our capping machines so that you get the perfect seal every time no matter what cap type or material. Learn more about our bottle filling machinery here.

Mars' premium wholesale bottle filling and capping machine is incomparable in terms of performance, accuracy, and safety when it comes to filling your production needs. Invest in your equipment with the confidence of improving efficiency, increasing output and ensuring a consistent fill in every bottle filled and capped. Opt For Mars for standard and inventive solutions in which will allow you to bring your production line to a new extraordinary level. Explore more about our capping solutions here.

When it comes to buying a bottle filling and capping machine for your business, the decision can be overwhelming. Several things must be considered First of all the size and type of bottle you plan to fill. Machines are set up to accommodate several bottle sizes and shapes so you will want to find one that fits your requirements. It is also important to take notice of the machines speed and efficiency. The capacity of the machine must meet your business requirements for smooth running. Finally, find a machine that is simple to use and service! To keep it running with less trouble makes you more productive. Check out our bottle capping machines here.

Bottle Filling and Capping Machines and What to Do When It Breaks! Whilst bottle filling and capping machines are great equipment to have in your business, there can be things that sometimes go wrong. Leakage during filling is a frequently encountered problem that may be due to improper seals or malfunctioning equipment. To prevent it, the best is to keep checking and maintaining the machine so that everything operates in good conditions. A further problem is that the bottles may be misaligned during capping, causing defective capped bottles. Aimed capping and correct alignments will minimize this. Simply by addressing these common problems when they arise, your bottle filling and capping machine will continue producing the same predictable, yet desired results.