4 Cavity Full Electric Servo Motor Type Automatic PET Bottle Blowing Machine Price in Nigeria

- Overview

- Recommended Products

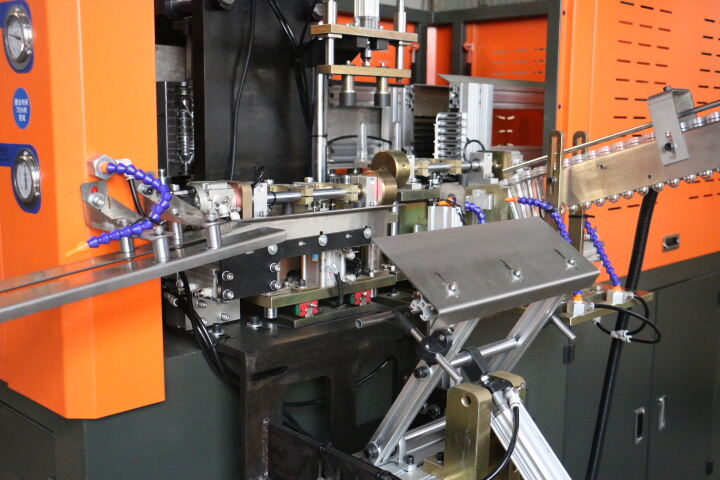

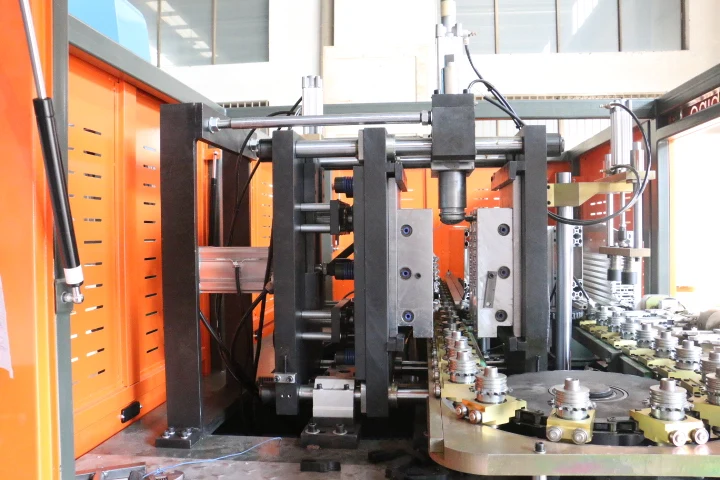

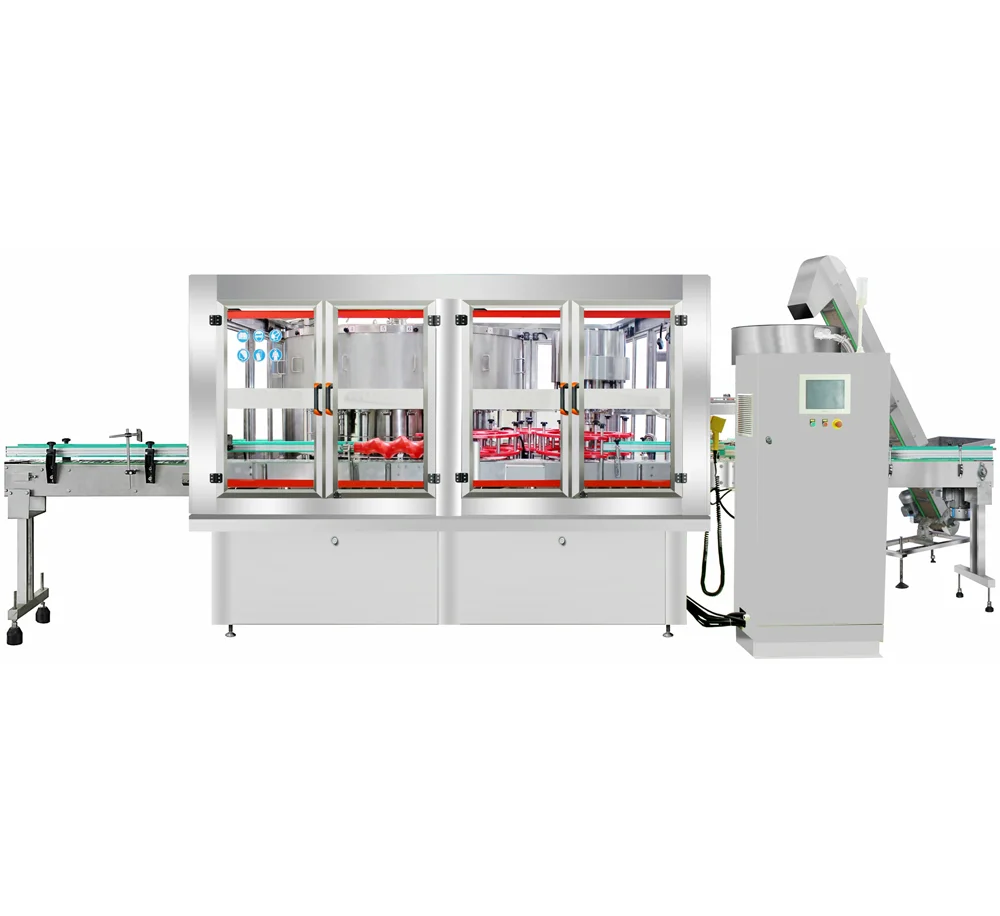

Introducing, the Mars 4 Cavity Full Electric Servo Motor Type Automatic PET Bottle Blowing Machine, the perfect solution for businesses looking to boost their production capacity and efficiency. This state-of-the-art machine is designed to meet the high demands of the packaging industry in Nigeria, offering superior performance and reliability.

With its advanced servo motor technology, this PET bottle blowing machine ensures smooth and precise operation, resulting in high-quality bottles with consistent wall thickness. The 4 cavity design allows you to produce up to 6,000 bottles per hour, making it ideal for small to medium-sized production lines.

One of the key features of the Mars PET bottle blowing machine is its fully electric design, which eliminates the need for costly and maintenance-intensive hydraulic systems. This not only reduces energy consumption but also minimizes downtime and maintenance costs, saving you money in the long run.

In addition, the machine is equipped with a user-friendly touch screen control panel, allowing operators to easily adjust settings and monitor production in real-time. This intuitive interface makes it easy to set up the machine for different bottle sizes and production requirements, ensuring maximum flexibility and efficiency.

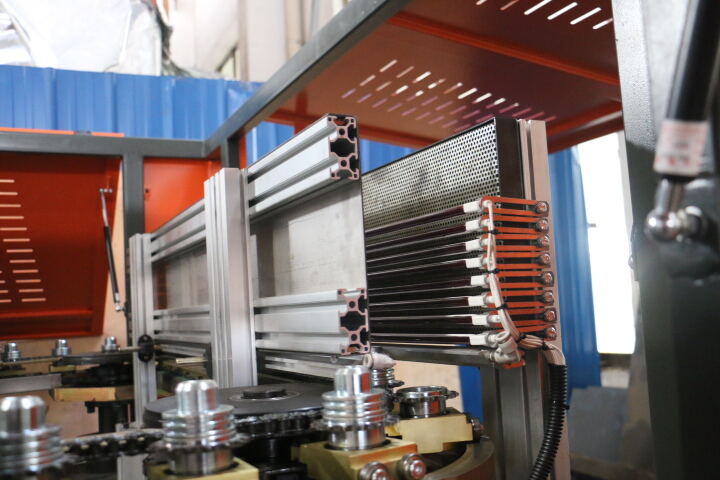

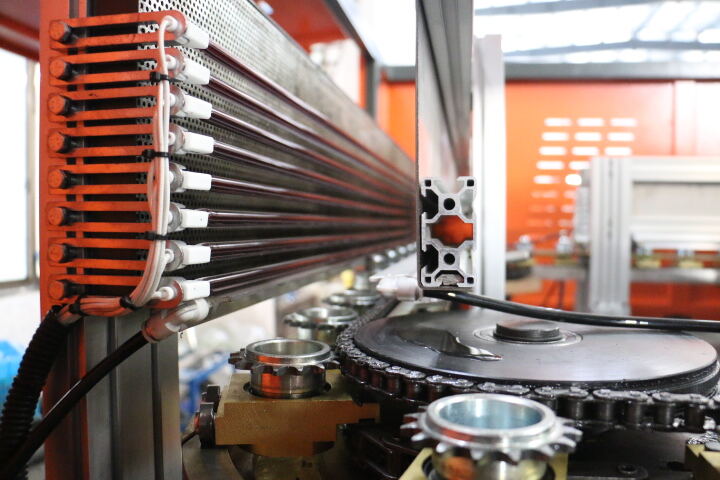

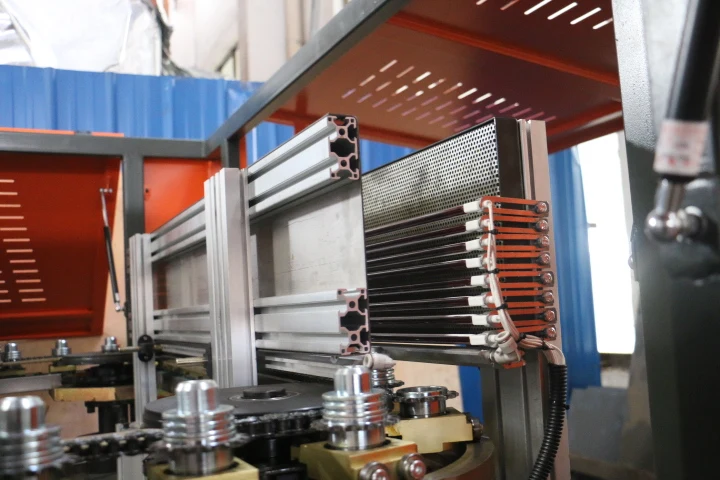

The Mars PET bottle blowing machine is also designed with productivity and safety in mind. It features automatic preform loading and unloading systems, as well as safety interlocks and alarms to prevent accidents and ensure smooth operation. The machine is also equipped with a high-quality infrared heating system, which ensures fast and uniform heating of preforms for consistent bottle production.

When it comes to price, the Mars 4 Cavity Full Electric Servo Motor Type Automatic PET Bottle Blowing Machine offers great value for money. Its competitive pricing makes it an affordable investment for businesses looking to upgrade their production capabilities and stay ahead of the competition.

The Mars PET bottle blowing machine is a top-of-the-line solution for businesses in Nigeria seeking a reliable and cost-effective way to produce high-quality bottles. With its cutting-edge technology, high efficiency, and competitive price, this machine is sure to take your production to the next level

4 Cavity Full Electric Automatic PET Bottle Blowing Machine Price In Nigeria

1. Technical parameter

Item |

BM-A4 |

|

Bottle type specification |

Cavity |

4 |

Theory output |

4500-5500 - 1000ml |

|

Max. volume |

2L |

|

Bottle mouth maximum overall diameter |

28-38mm |

|

Bottle biggest diameter |

105mm |

|

Bottle maximum height |

330mm |

|

Power specifications |

Light tube quantity |

40pcs |

Light tube power |

1.5KW |

|

Maximum heating power |

65KW |

|

All electric machine installation |

52KW |

|

Actual consumption |

40%-70% |

|

Air pressure specification |

Work pressure |

7-9kg/ cm2 |

Low-pressure gas consumption |

1000L/min |

|

Blow bottle pressure |

25-35kg/cm2 |

|

Higher - pressure gas consumption |

3000Ltr/min |

|

Frozen water specification |

Work pressure |

5-6 kg/cm2 |

Temperature range |

10℃ |

|

Consumption |

8000kcal/hr |

|

Frozen water flow |

138L/min |

|

Machine specification |

Size of the machine |

4.1x1.6x1.9 |

Weight of the machine |

3.9ton |

|

2. Main parts origin:

Components |

Brand, Origin |

PLC controller PLC |

MITSUBISHI |

Touch screen |

MITSUBISHI |

Cylinder |

SMC, Japan SMC |

Filter |

TPC, Korea TPC |

Magnet valve |

TPC, Korea TPC |

Photoelectric switch |

OMRON, Japan |

Contactor |

Schneider, France |

Proximity switch |

SICK, German SICK |

Sensor |

OMRON, Japan |

Switch power |

MEANWELL, Taiwan |

Frequency converter |

Mitsubishi, Japan |

Main Servo motor |

XINJIE CHINA |

Feeding Servo Motor |

XINJIE CHINA |

3. Spare parts list - free

Number |

Name |

Quantity |

1 |

heating lamps |

10 |

2 |

O-ring - total machine |

1 |

3 |

seal |

10 |

4 |

monkey spanner |

1 |

5 |

crossed spanner Slotted screwdriver |

1 |

6 |

high temperature wire, air pipe |

Each 5m |

7 |

inner hexagon spanner - set |

1 |

8 |

approach switch |

2 |

9 |

switch |

5 |