If you are considering a liquid packaging line for your facility, the right equipment is, of course, a necessity. At our site, Mars, you have lots of choices to find exactly what you're looking for. Regardless of whether you are a smaller company just getting started or a massive multinational, we have the knowhow and the equipment to drive your production capability and the quality of your products and in this article, we are going to take a look at some of the standout features and advantages of our liquid filling lines.

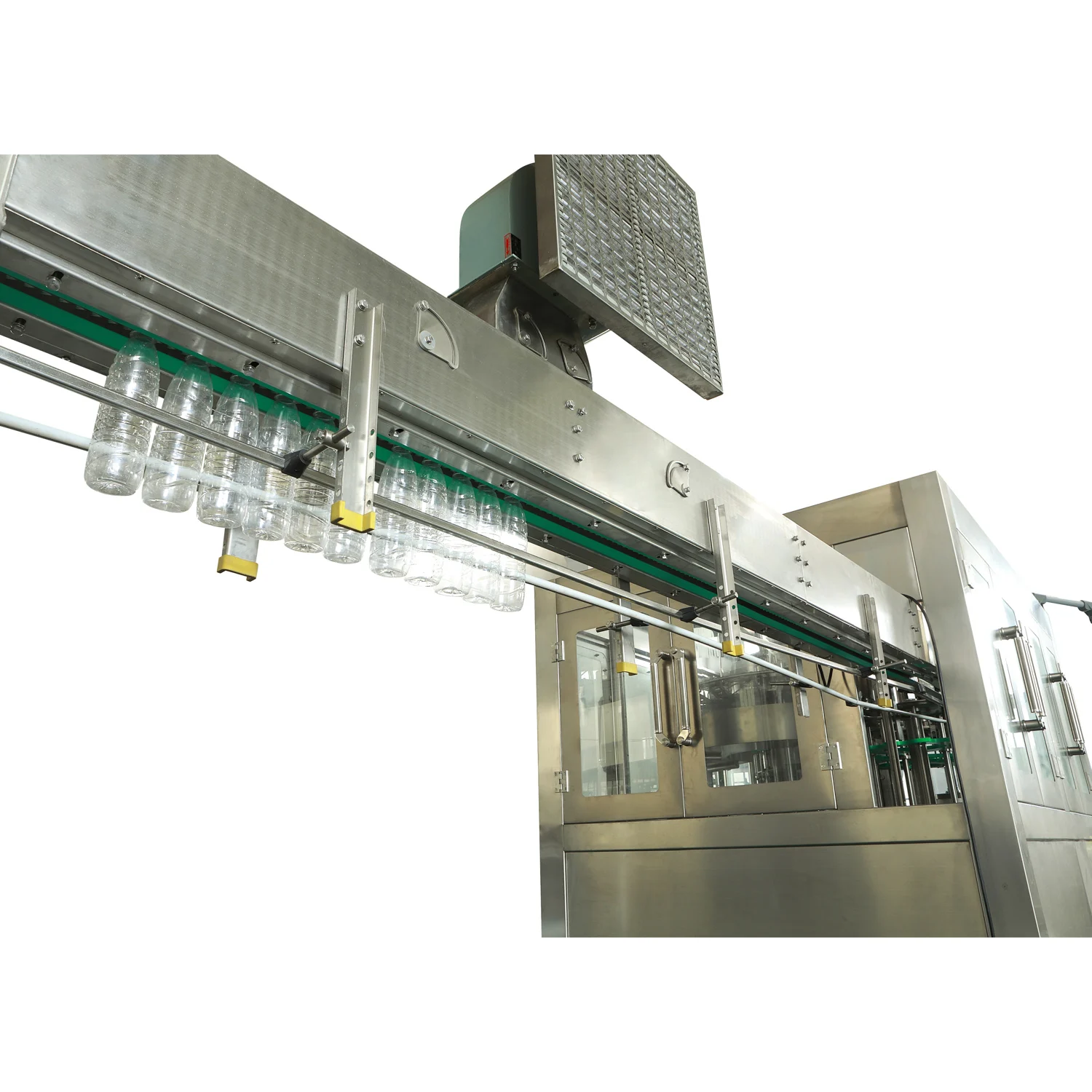

At Mars, we understand the importance of wholesale buyers returning to efficient, reliable equipment. The liquid filling lines we design are guaranteed to meet your production needs. Equipped with automatic handling of bottles and precise bottle filling, our machines can save you time and minimize waste. This means, you can create more items in less time, without compromising quality.

You don't have to break the bank when it comes to purchasing high-quality liquid filling machinery. At Mars we make products that are safe for your pet, satisfy your pet's needs, and are easy to use and affordable. The workmanship and quality of materials cannot be surpassed. This makes sure your investment is worth it in the long run because it will be less costly to maintain and repair in the future. And our equipment is made to promote energy efficiency, saving you money on the cost of running your systems.

Maxime@Adeneli Com Your Production Process At our filling lines you reap the benefits of both volume as well as innovation. And by using automations, you remove a lot of manual work from your process and streamline your production line. This has led to more work and greater capacity to fill higher and higher demand. Our machines are also relatively easy to integrate with other machines in your production line, and give you a seamless workflow that will not bring down your operations at any step.

We realize that every company's production line is different, so we give you the option to customize our liquid filling systems. If you require the system to accommodate multiple sizes of bottles, different liquor viscosities or would like to incorporate other functions (capping, labeling, etc.), we are able to customize a system to suit your needs. This agility means you can respond to shifts in the market or stay competitive in your industry.