One of the primary efficiencies of using a glass bottle can depalletizer machine is efficiency. These machines have the capability to wash, fill and seal many bottles in a small duration cycle saving time and enhancing productivity. What's being produced meets high demands without losing quality. Also, the bottle rinsing filling capping machines have easy and intuitive operation and maintenance. This enables the operators to learn how to run the machine and keep it running with limited downtime.

One more significant benefit of bottle rinsing filling capping machine is uniformity. These machines are automated and work the same for each activity and that makes sure also that during rinsing, filling up, and capping of bottles it is standard quality. One such uniformity useful in production is the ability to control quality and satisfy customers. The bottle rinsing filling capping machine is conveniently operated and can be connected directly with the preceding machinery to form a whole producing line upon customers' requests. It's also easy to adjust or change for different bottles of various kind for size and volume.

In addition to that, bottle rinsing filling capping machine are made keeping in mind of hygiene. Such machines are provided features in the form of cleanliness preventative mechanisms such as sterilization mechanism and enclosed filling chamber. This is simply to guarantee that any bottled beverages are safe and adhere to legal specifications. With a bottle rinsing filling capping machine manufacturers can ensure that this level of cleanliness is upheld at all times during the production process.

Mars will have a set of solutions that accommodate the production needs of wholesale buyers to buy the best bottle rinsing filling capping machine. Regardless of whether you operate as a small shop or a huge factory, Mars has readily available models for your business. The Mars X500 for instance is a small, powerful machine if you are new to the business or have a small business. What it does provide, however, is everything you need in regards to separating and filling bottles—without consuming your production floor with clunky machinery.

Mars Bottle Rinsing Filling Capping MachinesThere are many advantages offered to manufacturers by designs from Mars, namely a filling capping machine bottle rinsing, including: efficiency of their equipment consistent product quality hygienic construction practices. Vendors can select from these models how they get the quality of machine that fits their production requirements. With a Mars bottle washing filling capping machine, manufacturers can rest assured that their bottled drinks are reliable ad consistent to the highest possible standard and will surpass customer expectation as well as all necessary regulations.

If you are in the part of needing a bottle rinsing filling capping machine for your product line, it is critical to choose a trustworthy manufacturer who will provide you with an excellent drink plant design and high-quality merchandise. You can start looking for them online. Many manufacturers have websites that will tell you more about what they offer. You can also attend industry trade shows and expos where you will be able to see machinery in action and speak with manufacturers face-to-face. Another possibility is to seek recommendation from other businesses in your line of work who might have interacted with such machines.

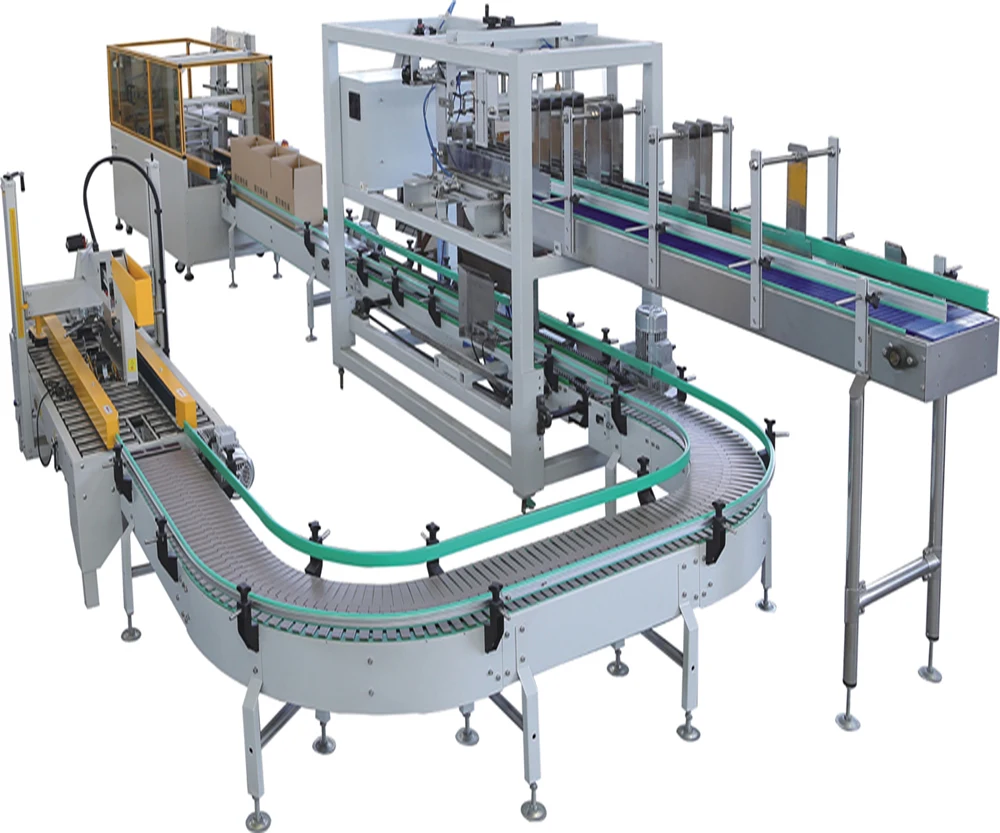

Bottle Rinsing Filling Capping Machines Bottle rinsing filling capping machines are used to bottle your juice beverage, water, with the turning type sent bottle structure and the balance wheel. Similarly such machines may be adapted for automation so that time and labor costs can be reduced. With a bottle rinsing filling capping machine, you are able to fill each bottle to precision and seal it accordingly; lessening the chances of spilling or contamination. This can also result in higher quality product and happier customers. Furthermore, they are perfect for meeting production schedules and ensuring your business rises to the demand as it continues to grow.