- Overview

- Recommended Products

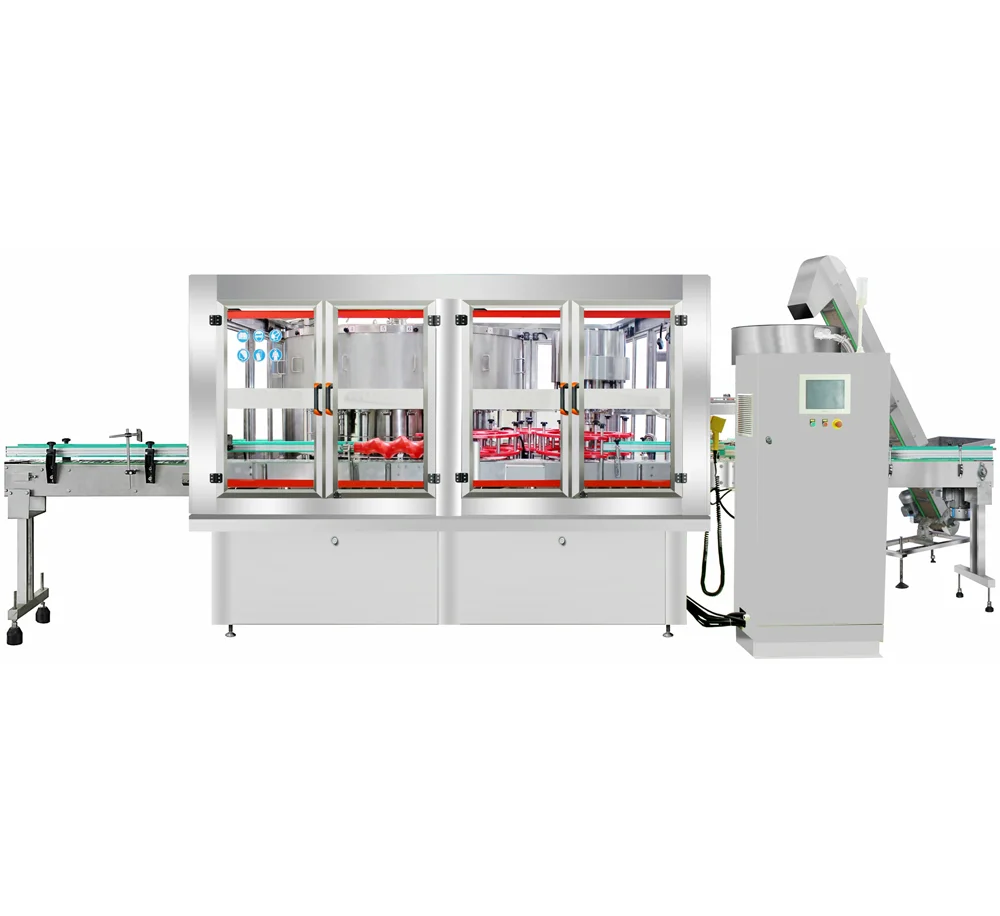

Full Automatic 2000bph Glass Bottle Crown Cap Sealing Corking Machine

1, Bottle caps automatically goes into bottle caps slot by adopting cap-pulling device. It goes to press and seal the caps on the bottle under helping of air compression. In order to the machine can fit on capping on various bottle volumes, and considering multi-usages in this machine, so it is adjustable on machine design. It has more advantages on well-structure, good outlook, small volume, low weight, wide using range, easy dismissible and maintenance, and low quotiety of bottle broken.

2. Usages and Useful Ranges

This machine is suitable for bottle volume of 250ml, 375ml, 500ml, and 625ml at height of bottle from 203-287ml in normal standard to press and cap the bottle through changing bottle-entry pulling wheel and central pulling wheel and baffle.

3. Main Specifications and Technical Parameter

|

Item. |

Model |

YG-6A |

|

1 |

Capping heads |

6 |

|

2 |

Production capacity |

2300B/H(speed adjustable controlled by inverter) |

|

3 |

Applicable Bottle capacity |

250ml, 375ml, 500ml, 625ml etc |

|

4 |

Bottle specification and limit deviation |

|

|

A: bottle outside diameter: Φ58~Φ76mm(±1) B: bottle height: Φ203~Φ287mm(±1.5) C: bottle neck outer diameter: Φ26.3mm(±0.20) D: bottle neck inner diameter: Φ16mm(±0.5) E: bottle inner pressure: 5-8MPA |

||

|

5 |

Applicable cap type |

Crown cap |

|

6 |

Cap specification and limit deviation |

|

|

A: Cap inner diameter:Φ26.3mm(±0.10) B: Cap height: 6.0-6.6mm(±0.05) C: Cap thickness: 0.28mm±0.02 D: Cap edge diameter: Φ32mm±0.25 |

||

|

7 |

Cap sorter motor power |

0.25Kw |

|

8 |

Main motor power |

0.75Kw |

|

9 |

Overall dimension |

1000×700×2000mm |

|

10 |

Weight |

650Kg |

when you send inquiry,please also included the capacity and bottles shape and bottle volume you need to work on the machine, it is easy and accurately for us to recommand a right machine!

If any special,our manufacture also can design the machines according your requirement