Automatic Thermal Heat PE Shrink Group Wrapping Machine for PET Bottled Water Juice Carbonated Beverages New Condition Motor

- Overview

- Recommended Products

Introducing, the Mars Automatic Thermal Heat PE Shrink Group Wrapping Machine, the perfect solution for packaging PET bottled water, juice, and carbonated beverages with precision and efficiency. This top-of-the-line machine is in new condition and is equipped with a powerful motor that ensures reliable and consistent performance.

Say goodbye to manual wrapping and hello to the convenience of automatic packaging with the Mars Shrink Group Wrapping Machine. This advanced machine is designed to streamline the packaging process, making it faster and more efficient than ever before. With its automatic thermal heat PE shrink technology, you can trust that your products will be securely wrapped and protected during transport and storage.

The Mars Shrink Group Wrapping Machine is versatile and can accommodate a wide range of bottle sizes, making it the perfect choice for businesses of all sizes. Whether you're packaging small bottles of water or larger bottles of juice or carbonated beverages, this machine can handle it all with ease. Plus, its compact design makes it easy to integrate into your existing production line without taking up too much space.

Not only does the Mars Shrink Group Wrapping Machine offer unparalleled convenience and efficiency, but it also delivers exceptional results. Your products will look professional and appealing, thanks to the tight and secure wrapping provided by this machine. Plus, the thermal heat PE shrink technology ensures that each package is sealed tightly, protecting your products from damage or contamination.

Invest in the Mars Automatic Thermal Heat PE Shrink Group Wrapping Machine and take your packaging process to the next level. With its reliable motor, versatile design, and exceptional results, this machine is a must-have for any business looking to improve their packaging efficiency and quality. Upgrade your packaging process today with the Mars Shrink Group Wrapping Machine and experience the difference for yourself

Automatic PET Bottle Thermal Shrink Wrapping Machine

Characteristic:

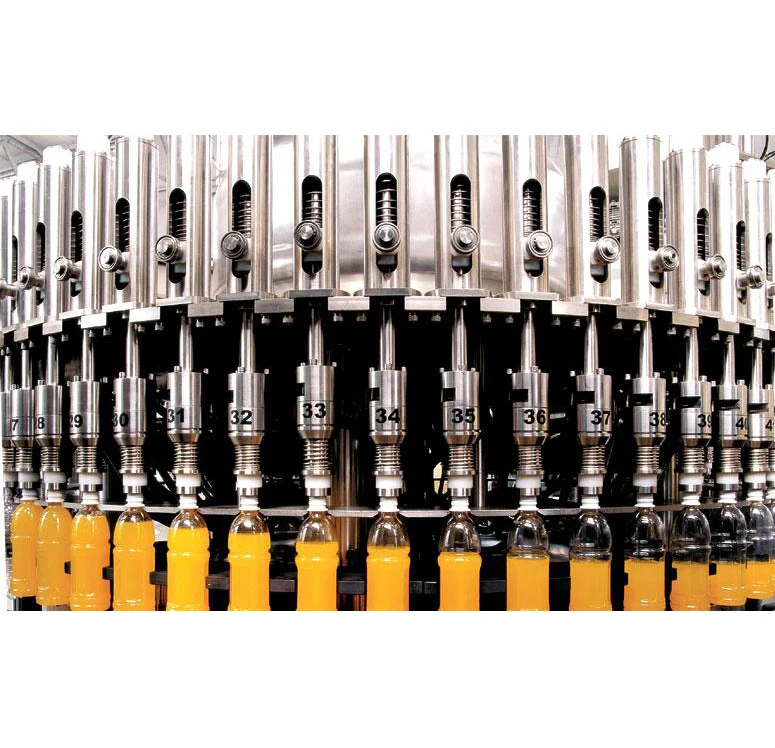

1. Specially designed for the full automatic packaging production line of beer, beverage, pure water, fruit juice, dairy products, etc.

2. With full automatic functions of bottle transfer and arrange, membrane packing, sealing and cut, shrinkage, cooling and shaping, etc.

3. Using advanced constant temperature membrane heat binding technology in the world with clear and secure seal.

4. The quick seal cooling structure guarantee that the seal has higher strength even if under high speed production condition.

5. Adopt with PLC automatic program circulation control with stable and reliable performance.

6. The original imported guide bar cylinder guarantee correct operation and durable

7. The inductive switch controls the membrane transfer system to reliably adjust and control the membrane transfer length with less loss

8. All the transfer system is controlled by frequency changing devices with stable and smooth transfer speed

9. Unique thermal passage with 2 sets of centrifugal thermal air circulation system that has an equal heat distribution with beautiful and secure shrinkage effect

10. 3 layers of heat insulation treatment with good insulting property, quick temperature rise and energy saving.

11. The enhanced cooling shaping passage can quickly turn the packing membrane into high strength status that is conveniently stored and transported

12. It is easy to change the packaging combination and bottle type to integrate the multi-function into one machine

Automatic PET Bottle Thermal Shrink Wrapping Machine Specification:

Dimension for the whole unit: |

L5500mm×W3200mm×H2100mm |

Thermal shrinkage passage dimension: |

L1800mm×W650mm×H450mm |

Max. package dimension: |

L600mm×W400mm×H350mm |

Shrink film material: |

PE, PVC, POF |

Shrink film thickness: |

0.03-0.15mm |

Packaging speed: |

8-10Packages/minute |

Operating power supply/power: |

380V, 20KW |

Sealing and cutting time/temperature: |

0.5-1.5s, 140PoPC-160PoPC |

Operating air pressure: |

0.6-0.8Mpa |

Air consumption: |

0.5m3/minute |

1. MARS company can provide one stop service including whole factory design, product solution design, abroad installation, worker training, spare parts supply etc.

2. MARS company have professional design team, our engineer can draw bottle samples and flow chart of workshop for you

3. MARS company give you the best quotation for all kinds of beverage production, only you can tell me which kind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass, etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General operation manual/maintenance book

3. After two year guarantee, the seller provides payable spare parts and technician’s VISITING maintenance service