- Overview

- Recommended Products

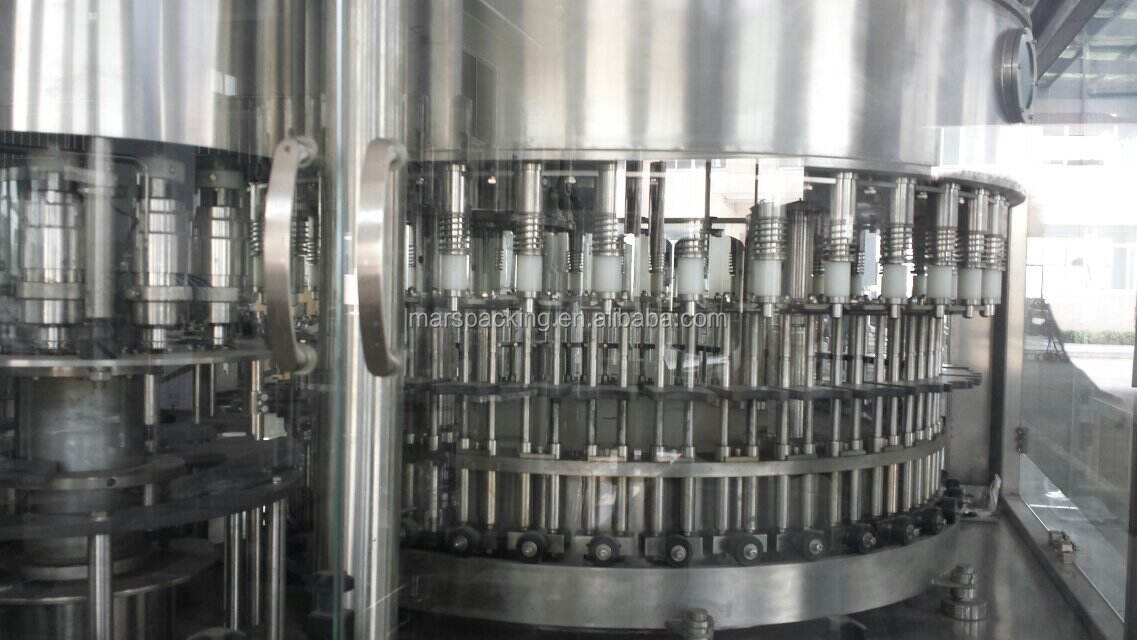

This machine has a compact structure, perfect control system, easy to operate and highly automated

The parts contact with product is made of quality SUS, anti-corrosive, and easy to clean

By adopting high speed filling valve, the liquid level is precise and no waste. That guarantees the demand of filling technology

The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap

This machine has a high efficient cap arranging system, perfect cap feeding and protection device

Equipped with perfect clean management system to ensure the bottle clean

Only by changing the star-wheel, can realize to fill the changed bottle shape

The machine adopts perfect overload protective device can ensure the operator and machine safe

This machine adopts adjustable frequency converter

The main electric components, frequency, photoelectric switch, proximity switch, electric control valves all adopt imported components, which can ensure the quality performance

The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc

The electric components and pneumatic components are all introduced from world famous brand products

Introducing, the Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine, the latest innovation in water bottling technology. This state-of-the-art machine is designed to streamline the process of bottling drinking water, making it easier and more efficient than ever before.

The Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine is perfect for small to medium-sized businesses looking to expand their water bottling capabilities. With its sleek design and user-friendly interface, this machine is easy to set up and operate, requiring minimal training for staff to use effectively.

This bottling plant machine is equipped with cutting-edge technology that ensures the quality and safety of the water being bottled. The machine is made of high-quality materials that are durable and long-lasting, ensuring that your investment will serve you well for years to come.

One of the standout features of the Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine is its automatic operation. This means that once the machine is set up and the bottles are loaded, it will fill, cap, and label the bottles without any manual intervention, saving you time and labor costs.

In addition, this machine is designed to be highly efficient, with the ability to bottle up to 2000 bottles per hour. This makes it ideal for businesses with high production demands, ensuring that you can keep up with customer orders and demand.

The Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine is also versatile, with the ability to bottle different sizes of PET bottles ranging from 200ml to 2 liters. This means you can cater to a variety of customer preferences and market demands with ease.

The Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine is a reliable and efficient solution for businesses looking to expand their water bottling operations. With its quality construction, automatic operation, and high production capacity, this machine is the perfect addition to your production line. Invest in the Mars’s Automatic PET Bottle Drinking Water Bottling Plant Machine today and see your bottling business reach new heights of success

Automatic PET Bottle Drinking Water Bottling Plant Machine

This series of mineral Water Filling Machine are applied to the production of pure water, mineral water, it integrates bottle washing, filling and capping into one body of this machine. It is very convenient to change bottle size by means of advanced bottle conveying technology--bottleneck clamping & bottle suspending technology.

Main Feature for Plant Water Bottles:

Origin of Main Parts for Plant Water Bottles

Item |

Part Name |

Brand name |

1 |

Frequency converters |

MITSUBISHI

|

2 |

PLC |

MITSUBISHI

|

3 |

Touch screen |

MITSUBISHI

|

4 |

Electricity panel |

Well organized

|

5 |

Photoelectricity Control parts |

OMRON

|

6 |

Pump |

CHINA

|

Mars Main Technical parameters for Plant Water Bottles

| |||||||

Model |

CGF14125 |

CGF18186 |

CGF24248 |

CGF323210 |

CGF404012 |

CGF505012 |

CGF606015 |

Heads |

14-12-5 |

18-18-6 |

24-24-8 |

32-32-10 |

40-40-12 |

50-50-12 |

60-60-15 |

Production |

3000-4000 |

6000-7000 |

9000-10000 |

14000-15000 |

17000-18000 |

22000-24000 |

25000-26000 |

Suitable bottle diameter - mm |

φ=50-100 H=170 330-1500ml |

||||||

Spraying pressure |

2~3 |

||||||

Motor power |

Main |

Main motor 2.2kw |

Main motor 3kw |

Main motor 4kw |

Main motor 7.5kw |

Main motor 9.5kw |

Main motor 12kw |

Power of |

0.75 |

1.1 |

1.5 |

2.2 |

2.2 |

3 |

4 |

Overall Dimension |

2100x1400x2500

|

2460x1720x2650 |

3100x2100x2650

|

3500x2500x2650

|

4600x1800x2650

|

5200x4500x3400 |

6500x4500x3400

|

Weight |

2500 | 3500 |

4200 |

5500 |

6800 |

7600 |

9800 |