A hollow passive cooler in beverages production They ensure that drinks such as juice, milk and even soda are safe for your consumption by eliminating dangerous germs. ON DEMAND: Join us to learn the basics of pasteurization and how this technology is used to help eHBs enter new markets.

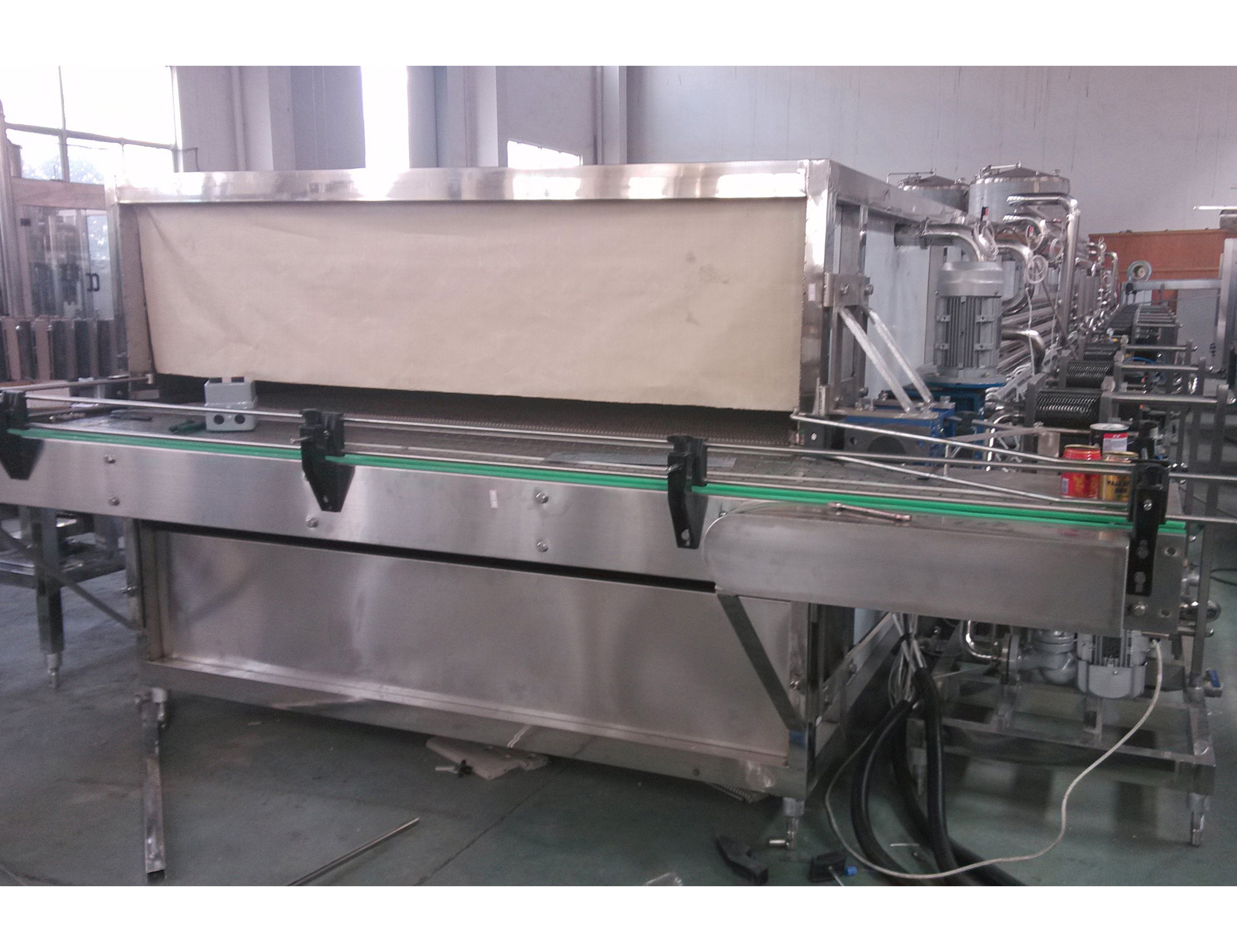

Tunnel pasteurisers, which use heat to kill germs and make drinks safe. The drinks travel through a long heated tunnel. So the germs need further to grow and die in this process, without any change for drink taste. It is kind of like literally the good germs hot tub.

Bottling Tunnel part for companies that have high number of drinks making. They are able to process large volumes of drinks in a brief time frame and save money as a result. Businesses can produce more drinks and sell them at a lower cost as such.

The fabulous thing about tunnel pasteurizers is their accurate temperature control. It means that firms are able to guarantee a precise pasteurisation temperature and time for the drinks. Namely, it avoids a drinkable and good-tasting material.

Tunnel pasteurizers are suitable for all form of container. No matter if a company bottling their drinks in glass, plastic or cans, one tunnel pasteurizer will work for all of them. This adds to their flexibility, as they are able to transition for packaging of various beverages without difficulty.

At Mars, we provide the necessary knowledge and understanding to fit tunnel pasteurizers into any company's production system. We have a set of experts who can assist companies in establishing their tunnel pasteurizers and help them get the most out of them. Supporting your transition to tunnel pasteurization