Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine

- Overview

- Recommended Products

Ø Obtaining quality in everything we do

Ø Fulfilling customers expectations

Ø Continuous improvement, innovation, and embracing change

Ø Creating a safe, productive, and rewarding work environment

Ø Having each employee contribute to Mars Packing Machinery's success

Ø Creating long-term value for customers and employees

Ø Delivering sustainable profitable growth built on pride, integrity, and respect

Introducing, the Mars’s Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine! This cutting-edge machine is designed to streamline and automate the bottling and sealing process for a variety of beverages, including yogurt, milk, litchi juice, and more.

With its advanced technology and precision engineering, this machine ensures that every bottle is filled to the perfect level and sealed tightly to preserve freshness and flavor. The hot filling capability allows for hot beverages to be bottled without compromising quality, making it ideal for producing a wide range of drinks.

The Mars’s Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine is easy to operate, with user-friendly controls and an intuitive interface. It is designed for efficiency and productivity, allowing for high speed bottling without sacrificing quality. The durable construction and reliable performance make this machine a valuable addition to any beverage production line.

Whether you are a small artisanal producer or a large-scale manufacturer, the Mars’s Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine is a game changer for your business. It can help you increase production output, reduce labor costs, and improve overall product quality. Plus, with its compact footprint, it won't take up valuable space on your production floor.

Invest in the Mars’s Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine today and experience the benefits of automated bottling and sealing. Say goodbye to manual labor and hello to increased efficiency and consistency. With its reliable performance and user-friendly design, this machine is sure to become an essential part of your beverage production process.

Trust in Mars for quality, innovation, and efficiency. Upgrade your bottling and sealing operation with the Mars’s Automatic PE Bottle Yogurt Milk Flavor Litchi Juice Drink Hot Filling Bottling Sealing Machine and take your business to the next level

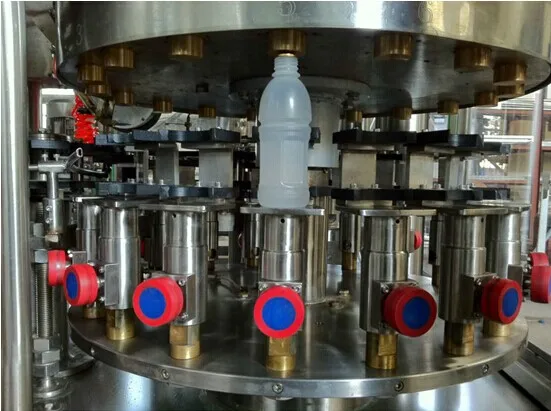

Yogurt Milk Filling Machine

1. Milk filling machine is used for production of bottled milk, lactate milk, soymilk, juice etc

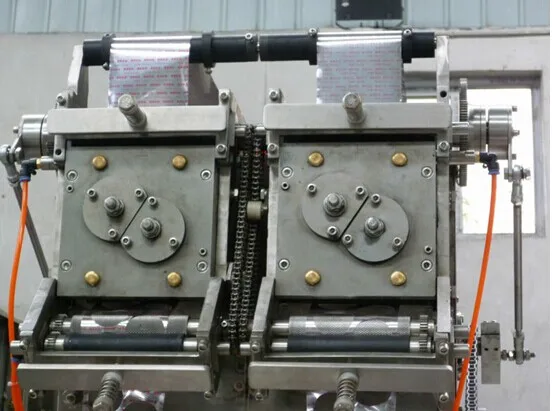

2. The machine completes the process of vacuum negative pressure filling, cap forming, capping (optional) and high frequency sealing automatically

3. Adopting world famous brand products from Germany, America, Japan, etc., including various sorts of valve and the system of PLC, optic-electronic and temperature control, pneumatic control and automatic lubrication etc

4. It is best choice for modernized enterprises

Yogurt Milk Filling Machine Main Technical Parameters:

Model |

MFS12/10 |

Filling Heads |

12 |

Sealing Heads |

10 |

Filling capacity |

250ml - 1000ml |

Filling capacity |

4000bottles / H - 250ML |

Bottle height |

110 - 180mm |

Bottle diameter |

38 - 68 |

Punch block |

Double punch heads |

Main motor power |

1.5KW |

Conveyor |

0.37Kw |

Foil forming machine |

0.18KW |

Ortex pump |

1.5Kw |

Electric heating power |

3.2KW |

3N-50Hz 380V/220V |

3N-50Hz 380V/220V |

Air Consumption |

1.6m3/min |

Overall dimension |

1.6×1.4×2.1 - m |

Weight |

1500Kg |

Our Mission

At Mars Packing Machinery our mission is to be the premier supplier and manufacturer of liquid and beverage bottling machine in multiple markets. We will continue to satisfy our customers with superior quality, value, and service

Our Values

Quality Policy

We will meet and exceed our customers expectations by utilizing our quality system and meeting our quality objectives through relentless continuous improvement

Corporate Description

Founded in 1998 Mars Packing Machinery Co., Ltd has grown to be a leading manufacturer of beverage bottling equipment. We can provide complete bottling line solution for water, carbonated drink and juice etc. We have established a broad portfolio of quality equipment and service that endures customers industry wide

Why our machine is better than other similar machines

1. Each water filling machine element that contacts with the liquid is made of high quality Stainless steel 304, if needed, SS 316 is also available

2. The water filling machine adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping

3. Most elements of the electrical system use famous international brand, such as Mitsubishi, Omron brand

4. The water filling machine obtain the advantages of good abrasive resistance, high stability, low failure rate, etc. The quality of the equipments reaches the international advanced level

5. Advanced technologies, human-machine interface touch screen and PLC program control are adopted in this machine.

6. Nozzles in the grab can guarantee the complete wash of the interior of the bottle

7. Easy to operate, save the cost of workers

Why our company is your correct choice in China

1. Small profits and quick returns is our business policy, so the water filling machine is worth every cent

2. We focus on advanced supply chain management, which can ensure the raw materials are with good quality and competitive price

3. Workers, engineers and boss of our company have spent more than 20 years in beverage machinery industry, so they have rich experience to provide Turn Key project Service

4. There are several engineers available to oversea service, the salary per day is cheap. As long as our customers need them, they can leave for your country as soon as possible, our principle to let our production line always runs normally

5. We can update the production status for our customer once per week, our target is to let our customer receive