De alta velocidad, totalmente automático línea de llenado de salsa máquina para precio al por mayor en Marte. Esta es una máquina para llenar recipientes de forma rápida con diferentes tipos de salsas, como kétchup, mayonesa y BBQ. Es capaz de satisfacer altas demandas de producción y es perfecta para empresas que necesitan aplicaciones rápidas y constantes de llenado de salsas. La característica de alta velocidad de esta máquina significa que el llenado puede ser rápido y preciso, ahorrando tiempo y mano de obra.

Al buscar la máquina automática perfecta para llenado de salsas, también las tenemos en Mars y son de primera línea, en las que muchas empresas confían. Nuestras máquinas son de alta calidad para uso duradero porque utilizamos únicamente la tecnología más avanzada y los mejores materiales. Ofrecemos máquinas automáticas para llenado de salsas a través de nuestro sitio web o mediante uno de nuestros excelentes empleados de ventas. Con precios competitivos y un servicio al cliente excepcional, estamos aquí para ayudar a las empresas en sus esfuerzos de llenado de salsas. Al elegir MARS llenadoras automáticas de salsas máquinas, las empresas pueden sentirse seguras de que están adquiriendo un producto líder en la industria, capaz de satisfacer cualquier necesidad de producción y cumplir con todas las expectativas de confianza.

Las llenadoras automáticas MARS son adecuadas para llenar todo tipo de salsas en envases de forma rápida y precisa. Funcionan mediante un proceso automatizado para garantizar un llenado fiable y exacto en cada ocasión.

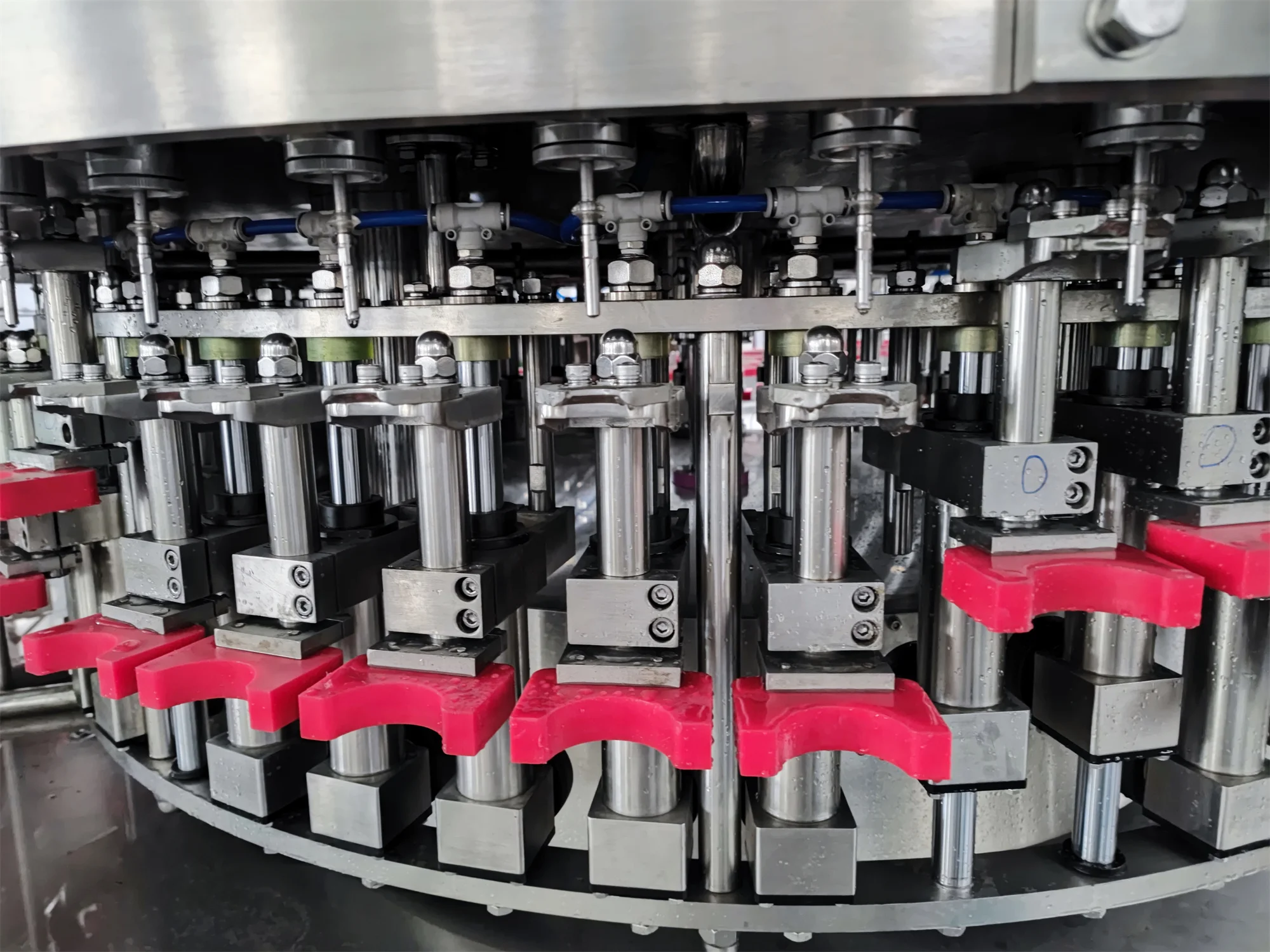

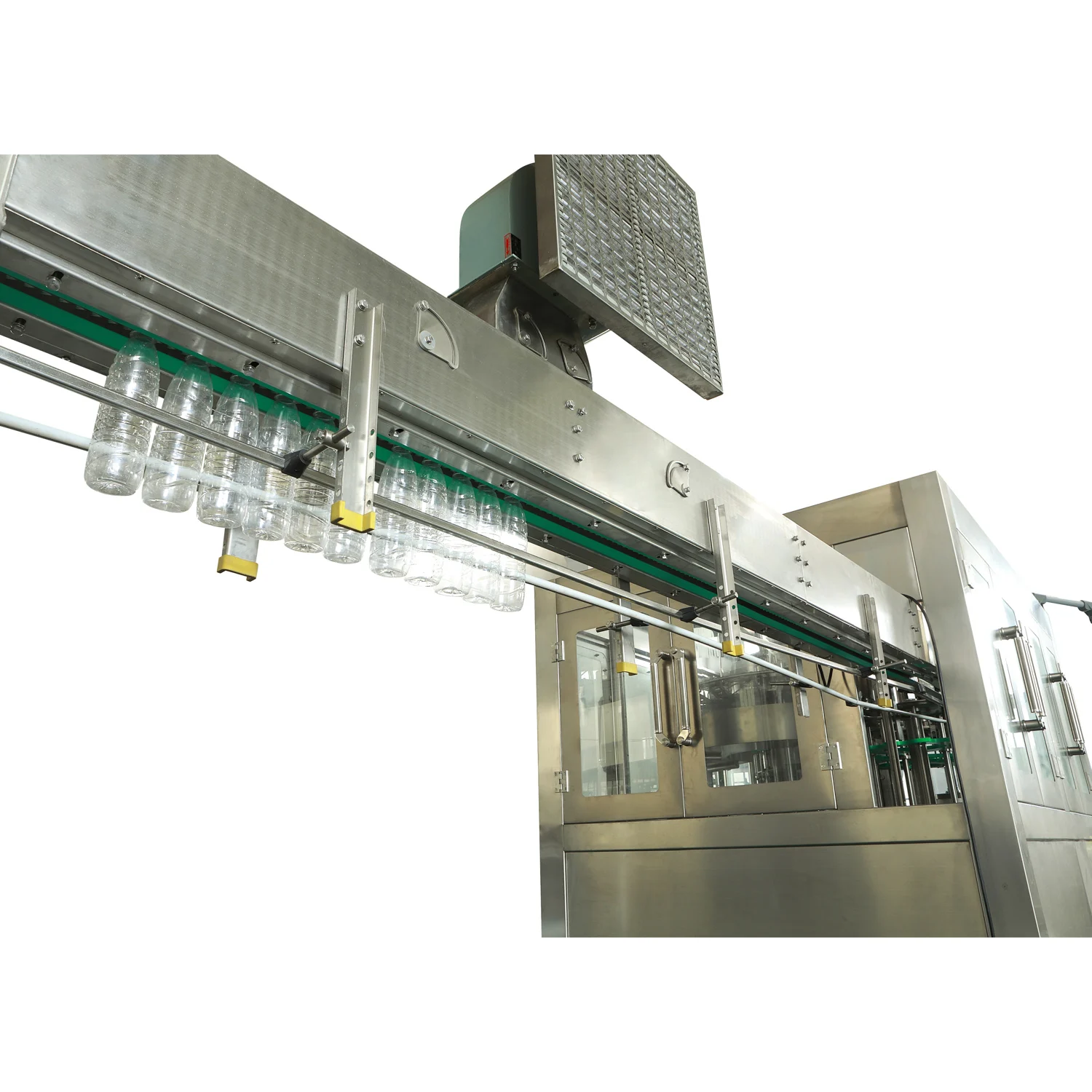

Primero, los envases vacíos se introducen en la máquina a través de una cinta transportadora . Luego, avanzan a lo largo de la cinta hasta una estación de llenado, donde pasan debajo de la boquilla de una cabeza vertical de medición y llenado. A continuación, la salsa se bombea desde un tanque de reserva hacia la boquilla, que mide la cantidad precisa de salsa que se depositará en cada paquete.

El proceso de llenado de salsa es automatizado, y la máquina avanzada de alta velocidad garantiza que el flujo de salsa sea cuidadosamente monitoreado. En consecuencia, el ordenador de llenado controla la velocidad de llenado de la máquina, asegurando que se llene un volumen definido en cada recipiente. Además, la máquina está equipada con una cinta transportadora de servicio que alimenta los recipientes a las estaciones de llenado y traslada los recipientes llenos hasta la estación de tapado. Los recipientes llenos son cerrados y expulsados de la máquina para su etiquetado y empaquetado. Algunos desafíos asociados con la máquina incluyen los siguientes: una boquilla obstruida, ya sea que esté en línea o desalineada; en cualquier caso, habrá derrames de salsa, lo que a pesar de ello puede provocar marcas por derrame y limpieza de emergencia, reanudación y producción, limpieza de la boquilla, y su alineación nuevamente a la posición original. En segundo lugar, el llenado inconsistente en algunos recipientes contribuye a que no se llenen a niveles óptimos. Esto puede deberse al funcionamiento inadecuado del sensor y de la válvula de interbloqueo O utilizada para determinar el volumen del llenado. Algunos de los desarrollos recientes a los que puedo acceder en el llenado de salsa Mars incluyen la integración de tecnología de software inteligente de detección que me permitirá ajustar la nivelación general de las tasas de llenado mediante el aumento del sensor y el dato controlado por el dispositivo de detección. Este avance ha contribuido a reducir el nivel de derrames, promoviendo un entorno de trabajo limpio y cantidades menores de desperdicio.